Concrete Block Making Machine from China Concrete Block Machine Manufacturer

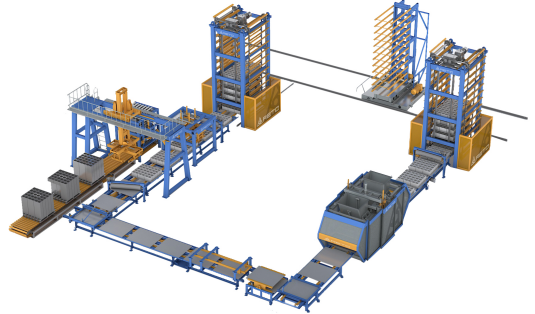

RT6A full automatic concrete block production line was an economical equipment, independently developed and produced by REIT Company in 2001, which can meet the diversified production needs of small enterprises and is cost-effective. It can produce various blocks, such as exterior wall blocks, interior wall blocks, flower wall blocks, floor slabs, river protection blocks, interlocks and curbstones.

RT6A full automatic concrete block produciton line was exported to Pakistan in 2005, suggesting that China designed and produced full automatic bricks production equipment entered into the international market for the first time.

REIT RT6A full automatic concrete block production line was sold to Korea in 2006, which was the first time that Chinese block equipment was sold to developed countries.

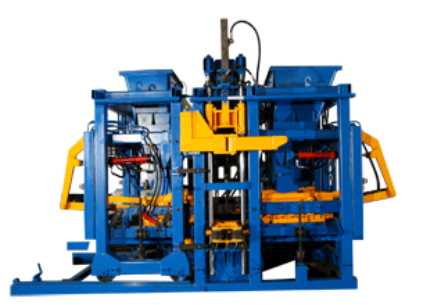

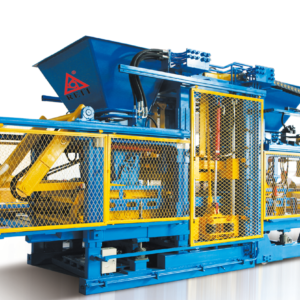

With Germany SIEMENS PLC Control, SIEMENS Frequency Conversion Technology, SEW Reducer, Servo motor and Double High-Dynamic Proportional valves, 360° Multi-shaft Concrete feed System & Heat Treatment on mould/main parts of brick machine, REIT RT6A is one of the most popular concrete brick making machines, with more economic investment cost, very suitable for someone to starting the brick-making business.

Product Feature:

REIT RT6A (6 stands for 6pcs of“400x200x200mm” hollow blocks per mould) has the production capacity of 1200pcs~1440pcs of 400x200x200mm concrete blocks each hour, and 135~162 cubic metre per day (8 working hours).

By changing different moulds, it’s able to produce different types of concrete hollow blocks, solid bricks, paver, interlock & curbstone.

REIT RT6A machine body is made of high-strength castings and welding of special materials, with good rigidity, vibration resistance and long service life. Its main machine adopt the rectangular steel of 10mm thickness.

The electrical system adopts German SIEMENS touch screen and programmable logic controller (PLC), including a safety logic control and fault diagnosis system. Hydraulic components use high dynamic proportional valves, which can adjust oil volume and pressure according to different production requirements. The four-bar guide synchronized gear ensures the precise operation of the tamper head and the mould.

Using table vibration & 360° compulsory feeding to shorten forming cycle and reach efficient production.

Technical Parameters:

Additional information

| Cycle Time | 15s~22s |

|---|---|

| Pallet size | 1300X670X45mm |

| Machine Weight | 6800KGS |

| Product height | 50~300mm |