In the ever-evolving construction industry, efficiency and productivity are paramount. Automatic concrete paver block making machines have emerged as game-changers, transforming the production of concrete pavers, an essential component of driveways, walkways, patios, and other paved surfaces. These machines leverage automation and advanced technologies to streamline the manufacturing process, ensuring consistent quality, reduced labor requirements, and increased production capacity. This comprehensive blog post delves into the world of automatic concrete block maker machines, exploring their types, advantages, working principles, and key considerations when selecting the right machine for your construction project.

Types of Automatic Concrete Paver Block Making Machines

There are two primary types of automatic concrete paver block making machines:

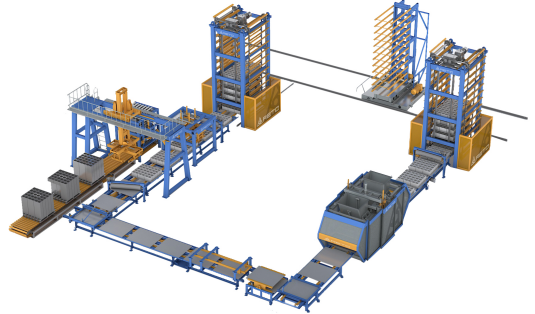

- Stationary Automatic Concrete Paver Block Making Machines:These machines are fixed in one location and are ideal for large-scale production of concrete pavers. They offer high production rates and are suitable for commercial and industrial applications.

- Mobile Automatic Concrete Paver Block Making Machines:These machines are portable and can be easily transported to different construction sites. They are perfect for small-scale projects or remote locations where stationary machines are not feasible.

Advantages of Automatic Concrete Paver Block Making Machines

Automatic concrete paver block making machines provide numerous advantages that make them a preferred choice for construction professionals:

- Efficiency:These machines significantly enhance production efficiency by automating various processes, such as mixing, molding, compacting, and curing.

- Quality Control:Automation ensures consistent quality and uniformity in the production of concrete pavers, minimizing defects and wastage.

- Labor Reduction:The automated nature of these machines reduces the need for manual labor, optimizing resource allocation and lowering production costs.

- Increased Production Capacity:Automatic machines can produce a large number of concrete pavers in a shorter time frame, meeting the demands of large-scale construction projects.

- Durability:Concrete pavers produced by automatic machines are known for their durability and longevity, making them ideal for heavy-duty applications.

Working Principle of Automatic Concrete Paver Block Making Machines

The working principle of automatic concrete paver block making machines involves several key steps:

- Mixing:The raw materials, including cement, sand, aggregates, and water, are thoroughly mixed to form a uniform concrete mixture.

- Molding:The mixed concrete is poured into molds or cavities of the block making machine. These molds determine the shape and size of the final pavers.

- Compacting:The mixture is subjected to high pressure or vibration to compact it and remove any air pockets, ensuring the strength and density of the pavers.

- Curing:After compaction, the pavers are left to cure for a specific period. This allows the concrete to gain strength and harden.

- Ejection:Once the curing process is complete, the finished pavers are automatically ejected from the molds and are ready for use in construction.

Key Considerations When Choosing an Automatic Concrete Paver Block Making Machine

Selecting the right automatic concrete paver block making machine is crucial to ensure optimal performance and efficiency. Here are some key factors to consider:

- Production Capacity:Determine the desired production capacity based on your project requirements. Consider the number of pavers you need per day or hour to meet your construction schedule.

- Paver Size and Shape:Choose a machine that can produce the specific paver size and shape required for your project. Different machines may have different mold options to accommodate various paver dimensions.

- Power Source:Consider the power source available at your construction site. Automatic block making machines can be powered by electricity, diesel, or gasoline.

- Automation Level:Evaluate the level of automation you require. Some machines offer advanced automation features, such as automatic material feeding, curing, and block ejection, which can further reduce labor requirements.

- Maintenance and Spare Parts:Consider the availability of maintenance services and spare parts for the machine. Regular maintenance is essential to ensure longevity and optimal performance.

For various of automatic concrete block making machines, please contact with block making machinery supplier from China, REIT. Then we will provide you quality machines information with block making machine prices.