In the realm of construction, the demand for efficient and cost-effective building materials is paramount. Concrete blocks have emerged as a versatile solution, offering durability, strength, and ease of construction. But what lies behind the production of these essential building components?

Enter the concrete block making machine, a revolutionary piece of equipment that has transformed the construction industry. In this post, we will explore the features, benefits, and impact of concrete block making machines.

Section 1: Understanding Concrete Block Making Machines

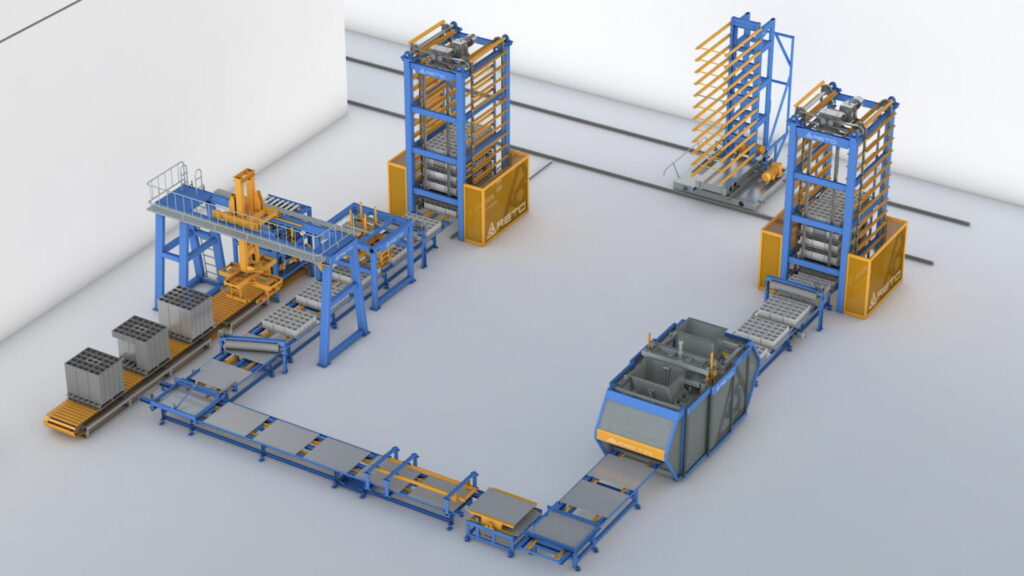

A concrete block making machine is a robust and automated device designed to produce concrete blocks of various sizes, shapes, and textures. These machines have revolutionized the process of manufacturing concrete blocks by streamlining the production and enhancing efficiency. Here are some key features and components of these machines:

- Mixing and Batching System: Concrete block making machines come equipped with an integrated mixing and batching system. This system ensures the accurate proportioning of raw materials such as cement, aggregates, and water, resulting in consistent block quality.

- Block Molding Unit: The heart of the machine is the block molding unit, which forms the concrete mixture into desired block shapes. This unit can be customized to produce different types of blocks, including solid blocks, hollow blocks, interlocking blocks, and paving stones.

- Vibrating and Compacting Mechanism: Concrete block making machines incorporate vibrating and compacting mechanisms that apply pressure to the block molds, ensuring proper compaction and consolidation of the concrete mixture. This results in stronger and more durable blocks.

- Curing and Drying Systems: After the blocks are molded, the machine provides curing and drying systems to facilitate proper curing of the blocks. This ensures the development of optimal strength and prevents cracking or deformation.

Section 2: Benefits of Concrete Block Making Machines

The adoption of concrete block making machines offers numerous benefits to the construction industry. Here are some notable advantages:

- Increased Productivity: Concrete block making machines significantly enhance productivity by automating the manufacturing process. These machines can produce blocks at a much faster rate compared to traditional manual methods, allowing for efficient completion of construction projects.

- Cost-Effectiveness: By automating the production process, concrete block making machines reduce labor costs and improve overall operational efficiency. Additionally, the use of concrete blocks as a building material can lead to cost savings due to their longevity, low maintenance requirements, and energy-efficient properties.

- Versatility and Customization: Concrete block making machines offer versatility in block shapes, sizes, and textures. This allows construction professionals to meet diverse project requirements and create structures with unique architectural designs. The machines can also be adjusted to produce specialized blocks for specific applications, such as insulation blocks or soundproofing blocks.

- Sustainable Construction: Concrete blocks are known for their sustainability. They can be made from locally sourced materials, reducing transportation costs and carbon emissions. Additionally, the thermal insulation properties of concrete blocks contribute to energy efficiency in buildings, reducing reliance on heating and cooling systems.

Section 3: Impact and Future of Concrete Block Making Machines

Concrete block making machines have had a profound impact on the construction industry. They have revolutionized the way concrete blocks are manufactured, offering speed, precision, and versatility. As technology continues to advance, we can expect further enhancements in machine capabilities, including increased automation, improved energy efficiency, and enhanced customization options.

The future of concrete block making machines holds promising potential. Advancements in material science and design will enable the production of even stronger and more sustainable blocks. Integration with digital technologies, such as artificial intelligence and machine learning, may further optimize the manufacturing process, leading to higher efficiency and quality control.