抽象的な

ブロック製造機の購入は、建設または製造企業にとって多大な資本投資を意味します。. この分析では、中国のレンガ造りの機械を調達するための説得力のあるケースを調べます 2025 グローバル市場, 5 つの主要な利点領域に焦点を当てる: 経済性, 技術の進歩, 生産の多様性, 品質保証, そして後方支援. この研究は、中国の製造業者が技術的に洗練された機器の生産を可能にする独自の産業エコシステムを培ってきたと仮定しています。, 全自動ブロックマシンなど, 非常に競争力のある価格帯で. これは品質に妥協することなく達成されます, しかし規模の経済によって, 成熟したサプライチェーン, そして熾烈な国内競争. 微妙な評価により、価値提案が初期購入価格を超えて、総所有コストの削減を含むことが明らかになりました。, 舗装ブロックや中空ブロックなどの製品の広範なカスタマイズ オプション, 充実したアフターサポート. 北米の企業向け, ヨーロッパ, そしてアジア, これらの統合された利点を理解することは、生産能力と収益性を向上させる戦略的に健全な投資決定を下すために最も重要です。.

キーテイクアウト

- 所有権の総コストを評価します, 初期価格だけではなく, より良い投資のために.

- 現代の中国のレンガ製造機モデルには、多くの場合、高度な自動化とテクノロジーが組み込まれています.

- さまざまなブロックタイプや金型のカスタマイズを提供するメーカーを探す.

- 品質管理認証と国際基準への準拠を検証する.

- 包括的なアフターサービスとスペアパーツの入手可能性を確認する.

- コンクリートを製造できる多用途のブロック製造機, 中空, そして舗装ブロック.

- 長期的な信頼性とサポートを確保するには、信頼できるサプライヤーを選択してください.

目次

- 理由 1: 初期価格を超えた費用対効果のパラダイム

- 理由 2: 先進的なものづくりと高度な技術

- 理由 3: 比類のないカスタマイズと生産の多用途性

- 理由 4: 堅牢な品質管理と世界基準の保証

- 理由 5: 合理化されたサプライチェーンと包括的なサポート体制

理由 1: 初期価格を超えた費用対効果のパラダイム

企業が重機の調達を検討する場合, 会話はしばしば価格から始まります. まだ, 最初の請求額に固執すると、より深刻な経済的現実が見えにくくなる可能性があります. 何, それから, ブロック製造機などの重要な産業機器の真の価値を構成します。? 中国のレンガ製造機の経済的優位性に関する議論は、単にレンガ製造機が優れているという単純な主張に基づいているわけではありません。 “安い,” ただし、総所有コストを包括的に理解した上で (TCO), 機械の稼働期間を通じて発生するあらゆる費用を包含する概念. 中国の製造業, 特に建設機械などの特殊な分野では, 所定の資本予算内で何が可能かを再評価できるレベルの効率を達成している.

総所有コストの分析

初回購入価格は単なるエントリーポイントです. 思慮深い投資家は将来を見据える必要がある, 機械のライフサイクル全体の財務状況を考慮する. これには運用コストも含まれます, エネルギー消費量や労働要件など. 維持費も含まれます, 定期的なメンテナンスとウェアラブル部品の交換をカバーします。. ついに, 機械の生産性と寿命を考慮する必要があります, 最終的に投資収益率を決定するのは.

現代の中国のレンガ製造機は、多くの場合、これらの TCO 原則を念頭に置いて設計されています。. 例えば, 多くのモデルはエネルギー効率の高い油圧システムとモーターを備えています, 長年の運用で電気代を大幅に節約できます. 同様に, 自動化への動き, 現代の特徴 完全自動ブロックマシン, 肉体労働への依存を減らす. これにより、人件費が削減されるだけでなく、人的ミスのリスクも軽減されます。, より安定した製品品質と材料の無駄の削減につながります. これらの長期的な節約額を初期資本支出と比較すると、, 経済論理が非常に明確になる. 初期費用の削減が促進剤として機能する, 収益性へのより迅速な道を可能にする.

中国製造業における規模の経済学

メーカーはどのようにしてこのような高度な機械をこの価格帯で提供できるのでしょうか? 答えは広大な空間にあります, 中国の相互接続された産業エコシステム. 数十年にわたる集中的な開発により、スケールメリットが単なる教科書的な概念ではなく、日常の現実となる環境が生まれました。. コンクリートブロック製造機のメーカーは、高度に発達した国内サプライチェーンの恩恵を受けています. フレームに使用される生の鋼材からすべて, 油圧ポンプへ, プログラマブルロジックコントローラーへ (PLC) 機械の頭脳を形成する, 専門業者から調達できる, 効率的, および地理的に近いサプライヤー.

この近接性と規模により調達コストが削減されます, 輸送コストを最小限に抑える, 生産スケジュールを短縮します. 熾烈な国内競争はイノベーションをさらに促進し、メーカーには継続的にプロセスを最適化するよう圧力をかけています。. 米国の海外バイヤーの場合, カナダ, またはロシア, このエコシステムは、高品質のブロック製造機のより手頃な価格に直接変換されます。. あなたは, 事実上, 世界の他の場所では再現するのが難しいレベルの産業最適化の恩恵を受けています.

関税と送料を回避して最大限の節約を図る

あらゆる国際調達に対応, 物流コストと輸入関税は重要な考慮事項です. 慎重な分析には、これらを最終的な陸揚げコストに織り込む必要があります。. 評判の良い中国のサプライヤーは世界的な物流において豊富な経験を持っています. 運送業者や通関業者との関係を確立している, 国際貿易の複雑さを効率的にナビゲートできるようにする. 多くの場合、正確な情報を提供できます。, 予期せぬ出費を防ぐ包括的な見積もり.

料金は地政学的要因に基づいて変動する可能性がありますが、, 経験豊富なメーカーは、調和されたシステムに関するガイダンスを提供できます (HS) 可能な限りスムーズな通関を確保するためのコードと文書. 知識豊富なサプライヤーと協力することで, 企業はこれらの変動費を効果的に管理できます, 中国製レンガ製造機の調達に固有の経済的利点を維持する. 目標は、潜在的に困難な物流上の課題を、投資戦略全体の予測可能な要素に変えることです。.

理由 2: 先進的なものづくりと高度な技術

中国の製造業に対する共通の、しかし時代遅れの認識は、真の革新ではなく単純な模倣であるというものだ. この見解は、過去 20 年間に起こった重大な変化を認識できていない. 今日, 建設機械の大手メーカーは単なる世界市場の参加者ではありません; 彼らは技術進歩の原動力です. 現代の中国のレンガ製造機はこの進化の証です, 多くの場合、西側諸国と同等またはそれを超える機能と自動化レベルが組み込まれています。. これらの機械の技術的中心部を調べると、精度へのこだわりが明らかになります, 効率, インテリジェントな操作.

オートメーションと PLC システムの役割

最新のブロック生産ラインの中核となるのはプログラマブル ロジック コントローラーです (PLC). PLC を機械の中枢神経系と考えてください。. これは、セメントや骨材などの原料の正確な測定と混合から、型の振動周波数や完成したブロックの最終的な積み重ねに至るまで、あらゆる動作をマイクロ秒の精度で調整する堅牢な産業用コンピューターです。.

中国の大手メーカーは、シーメンスや三菱などの世界的に認められたブランドの洗練された PLC システムを統合しています, 直感的なタッチスクリーンのマンマシンインターフェースと組み合わせる (HMI). これにより、オペレーターは生産プロセス全体をリアルタイムで監視できるようになります。, 簡単なタッチでパラメータを調整, 潜在的な問題が重大な障害になる前に診断します。. 全自動ブロックマシン, そのようなシステムに導かれて, 人間の介入を最小限に抑えながら継続的に動作できる. このレベルの自動化はもはや贅沢ではありません; これは比類のない一貫性を保証する基本的な機能です, 出力を最大化します, 職場の安全性を高めます. 原材料を驚くべき効率で高品質の建築部品に変える技術エンジンです.

振動と油圧技術の革新

コンクリートブロックの品質 - その密度, 強さ, 仕上がりは、主に圧縮と振動のプロセスによって決まります。. ここでは、原材料が金型に押し込まれ、固体ユニットに統合されます。. 中国のエンジニアリングが大きく進歩した分野です. 高度なシステムでは、テーブルとタンパーヘッドの同期振動を利用するようになりました。, 強力な力によって動かされる, 周波数制御モーター.

この技術により、振動力を正確に加えることが可能になります。, コンクリート混合物が型枠全体に均一に分散され、圧縮されていることを確認します。. その結果、ボイドの少ないブロックが得られます。, より高い圧縮強度, そしてより鋭い, より明確なエッジ. 高性能油圧システムとの組み合わせ, 圧縮に必要な巨大な圧力を提供します, この高度な振動テクノロジーが、優れたブロックと平凡なブロックを分けるものです. これが可能なマシン, 特殊な舗装ブロック機械など, 何十年にもわたって交通渋滞や過酷な気象条件に耐えることができる、高密度の連動舗装を製造できます。.

自動化レベルの比較

利用可能なオプションをより深く理解するには, 自動化の程度に基づいてマシンを分類すると役立ちます. これにより、企業は投資を特定の生産ニーズに合わせて調整できるようになります。, labor availability, and budget.

| 特徴 | マニュアルマシン | 半自動マシン | 完全自動ブロックマシン |

|---|---|---|---|

| Operation | Labor-intensive; requires multiple operators for material feeding, プレス, そしてdemolding. | Mix of automated processes and manual intervention; operator manages key steps via levers or buttons. | PLC-controlled; minimal human oversight required from raw material input to final block stacking. |

| Output Capacity | 低い (例えば。, 1,000-2,000 ブロック/日) | 中くらい (例えば。, 5,000-15,000 ブロック/日) | 高から非常に高い (例えば。, 20,000+ ブロック/日) |

| 一貫性 | Highly dependent on operator skill; potential for significant variation. | Good consistency due to automated pressing and vibration cycles. | Excellent consistency; every block is produced to the exact same specifications. |

| Labor Cost | High per unit produced | 適度 | Low per unit produced |

| 初期投資 | 低い | 中くらい | 高い |

| に最適です | Small-scale startups, コミュニティプロジェクト, or areas with very low labor costs. | Small to medium-sized enterprises (中小企業) looking to scale up production. | Large-scale commercial operations, major construction projects, established manufacturers. |

This table illustrates a clear trade-off. While a manual machine has the lowest entry cost, a 完全自動ブロックマシン offers vastly superior efficiency, 一貫性, and long-term profitability for any serious commercial venture.

理由 3: 比類のないカスタマイズと生産の多用途性

In a competitive market, the ability to adapt and diversify one’s product offerings is a powerful advantage. A construction material business may need to produce standard building blocks one day, decorative pavers the next, and specialized hollow blocks the day after. The capacity to meet these varied demands with a single piece of capital equipment is a defining feature of a wise investment. Chinese manufacturers excel in this domain, offering a degree of customization and versatility that empowers businesses to be agile and responsive to market needs. This flexibility is not an afterthought; it is engineered into the very design of the equipment.

The Power of Interchangeable Molds

The true genius of a modern block making machine lies in its modular design, specifically the system of interchangeable molds. The main body of the machine—the frame, the hydraulic press, the vibration system—is a universal platform. The specific product it creates is determined entirely by the mold set that is installed. A single China brick making machine can, したがって, be a multi-purpose production hub.

Imagine the possibilities. With one mold set, you can produce high-strength load-bearing concrete blocks for structural walls. By spending a few hours to swap out the mold, the same machine can be transformed into a hollow block machine, producing lighter units ideal for partition walls and insulation. Another mold change, and you now have a paver block machine, capable of manufacturing intricate, interlocking paving stones for driveways, パティオ, そして公共スペース. This capability is liberating. It means a business is not locked into a single product line. It can pivot its production based on client orders, seasonal demand, or emerging architectural trends. Reputable manufacturers offer a vast catalog of standard mold designs and, crucially, provide custom mold fabrication services based on a client’s specific drawings or requirements.

Producing a Spectrum of Block Types

The versatility extends beyond just shape. A well-designed machine allows for precise control over the raw material mix and compaction parameters. This enables the production of a wide array of concrete products with different properties.

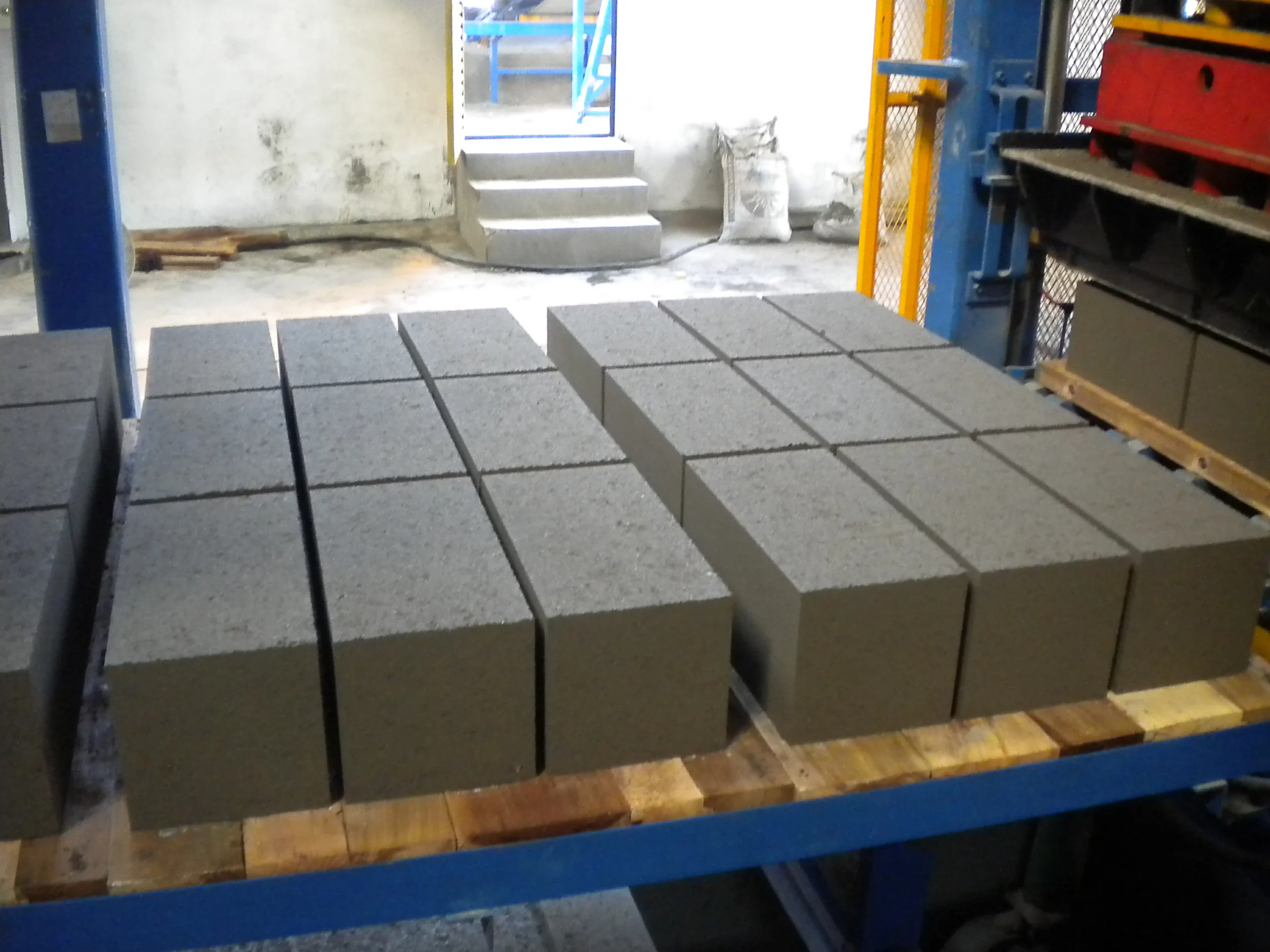

- Solid Concrete Blocks: The backbone of construction, used for foundations and load-bearing walls. The machine must provide immense compaction force to ensure maximum density and strength.

- 中空ブロック: These contain one or more large voids. They are lighter, easier to handle, and offer better thermal and acoustic insulation. A hollow block machine must ensure consistent wall thickness and sharp core definitions.

- インターロッキングペイバー: These require high aesthetic quality, precise dimensions for a tight fit, and exceptional surface durability to withstand abrasion and weathering. A paver block machine uses specialized vibration patterns to achieve a dense, smooth top layer.

- Curbstones and Slabs: より大きな, heavier units used for landscaping and infrastructure. The machine needs a robust frame and a powerful feeding system to handle the larger volume of material required for each cycle.

- フライアッシュレンガ: An environmentally conscious option that utilizes industrial waste. The process for making fly ash bricks requires different mix proportions and curing methods, which a versatile machine can accommodate. 探索 sustainable building solutions can open up new markets and government incentives.

The ability to produce this entire spectrum from a single production line fundamentally changes a business’s market position, turning it from a simple supplier into a comprehensive building solutions provider.

Comparing Material Properties for Different Applications

The choice of block type is dictated by its intended use. Understanding the material science behind these choices is key for any producer. The machine’s role is to reliably and consistently create products that meet these specifications.

| Property | 標準コンクリートブロック | Fly Ash Brick | Hollow Concrete Block |

|---|---|---|---|

| Primary Raw Materials | セメント, 砂, Aggregate (砂利) | フライアッシュ, Sand/Stone Dust, Cement/Lime | セメント, 砂, Aggregate (砂利) |

| 圧縮強度 | 高い (通常 15-30 MPa) | Moderate to High (10-25 MPa) | 適度 (Lower due to voids) |

| Density | 高い (approx. 2200-2400 kg/m³) | より低い (approx. 1700-1900 kg/m³) | 低い (approx. 1400-1800 kg/m³) |

| Thermal Insulation | 低い | 良い | Very Good |

| 吸収 | 適度 | 低い | 適度 |

| Primary Application | Load-bearing walls, 基礎 | 非耐力壁, infill masonry | 隔壁, exterior non-load-bearing walls |

| 環境への影響 | 高い (due to cement production) | 低い (utilizes industrial waste) | 適度 |

A superior block making machine provides the operator with the control needed to perfect the production of each of these types, adjusting vibration, プレッシャー, and cycle times to optimize for the specific material characteristics.

理由 4: 堅牢な品質管理と世界基準の保証

An investment in industrial machinery is an investment in reliability. A machine that suffers from frequent breakdowns, produces inconsistent products, or fails prematurely is not an asset but a liability. このため, an examination of quality control processes and adherence to recognized standards is not just a technicality; it is a fundamental part of the due diligence process. The narrative of Chinese manufacturing has shifted decisively towards a focus on quality, with leading companies implementing rigorous systems to ensure their products meet the expectations of a demanding global clientele. Placing trust in a manufacturer requires understanding their commitment to excellence, a commitment that should be evident in their materials, their processes, and their certifications.

From Raw Materials to Final Assembly

Quality cannot be inspected into a product at the end; it must be built in from the very beginning. For a block making machine, this principle starts with the selection of raw materials. A reputable manufacturer will use high-strength, certified steel (such as Q235 or manganese steel) for the machine’s main frame to ensure it can withstand the immense, repetitive stresses of hydraulic pressure and vibration for years without fatigue or deformation.

The scrutiny continues with key components. 油圧システム, motors, bearings, and PLC controllers are often sourced from internationally respected brands or from top-tier domestic suppliers who have themselves undergone stringent quality audits. During the manufacturing process, critical steps like welding are performed by certified technicians, often using robotic welders for perfect consistency. After fabrication, key surfaces are precision-machined to ensure perfect alignment of the mold and tamper head, a detail that is essential for producing dimensionally accurate blocks. ついに, the entire machine undergoes a comprehensive testing protocol before it is disassembled for shipping. This involves a no-load run to check all mechanical and electrical functions, followed by a load run where the machine actually produces blocks to verify its performance under real-world conditions. This meticulous, multi-stage approach is the bedrock of reliability.

Understanding Certifications: CE and ISO

In the world of international trade, objective, third-party certifications serve as a universal language of quality and safety. For machinery, two of the most significant are the CE mark and ISO 9001 certification.

-

CE Marking: の “Conformité Européenne” mark indicates that a product complies with the high safety, 健康, and environmental protection standards of the European Economic Area (EEA). For a block making machine, this means the equipment has been designed to minimize electrical hazards, includes necessary safety guards to protect operators from moving parts, and is accompanied by comprehensive technical documentation. While it is a European standard, the CE mark is recognized globally as a strong indicator of a manufacturer’s commitment to safety and engineering best practices.

-

ISO 9001: This is a global standard for Quality Management Systems (QMS). A company that is ISO 9001 certified has demonstrated that it has a systematic, process-driven approach to quality. This includes everything from how it handles customer orders and designs products to how it selects suppliers and manages its production floor. It is an assurance that the manufacturer has robust, repeatable systems in place to deliver a quality product consistently. When evaluating a potential supplier for a コンクリートブロック製造機, asking for their CE and ISO 9001 certificates is a crucial step.

The Importance of a Reputable Supplier

The machine itself is only part of the equation. The manufacturer behind it is equally important. A reputable supplier is a long-term partner, not just a one-time vendor. Such a supplier, like one with a legacy of engineering excellence, will have a track record of successful installations in various countries, including demanding markets like the United States, カナダ, そして韓国. They will be transparent about their processes, willing to provide detailed technical specifications, and able to offer references from past clients.

A reputable supplier understands that their success is tied to your success. They invest in their reputation by investing in the quality of their products and the satisfaction of their customers. They provide clear communication, realistic delivery timelines, and stand behind their product with a solid warranty. Choosing such a partner transforms the purchase from a simple transaction into a strategic alliance aimed at building your business’s production capabilities.

理由 5: 合理化されたサプライチェーンと包括的なサポート体制

The operational life of a block making machine begins the moment it is delivered. Its long-term value is profoundly influenced by the support structure that accompanies it. A technologically advanced and well-built machine can be rendered ineffective without proper installation, トレーニング, and a reliable source for spare parts and technical assistance. The most forward-thinking Chinese manufacturers have recognized that providing a superior product is only half the battle. They have invested heavily in creating comprehensive support systems and leveraging their logistical expertise to ensure their customers can maximize the productivity and lifespan of their investment, regardless of where they are in the world.

アフターセールスサービス: インストール, トレーニング, and Technical Support

The journey with a new machine should not be a solitary one. Leading manufacturers offer a suite of after-sales services designed to ensure a smooth transition and continued operational excellence.

-

インストールと試運転: Many suppliers offer the option to send their own experienced engineers to the customer’s site. These technicians oversee the assembly of the production line, ensure all electrical and hydraulic connections are correct, マシンを委託します, which involves the initial test runs to calibrate its performance for the local raw materials. This professional oversight eliminates guesswork and ensures the machine is set up for optimal performance from day one.

-

オペレータートレーニング: A machine is only as good as the person operating it. The manufacturer’s technicians will provide hands-on training for the local staff. This covers the day-to-day operation of the machine via its HMI, procedures for changing molds, routine maintenance tasks like lubrication and inspection, および基本的なトラブルシューティング. This transfer of knowledge empowers the customer’s team to operate the machine confidently and efficiently.

-

Remote Technical Support: In the digital age, assistance is often just a call or a video conference away. Manufacturers provide ongoing technical support to help diagnose and resolve issues remotely. With modern PLC systems, technicians can sometimes even access the machine’s diagnostics online to identify problems quickly, minimizing downtime.

This three-pronged approach—professional installation, comprehensive training, and accessible support—forms a safety net that protects the customer’s investment.

The Global Reach of Spare Parts Logistics

Every machine, no matter how well-built, has parts that will wear out over time. Molds, コンベアベルト, 油圧シール, and certain electrical components have a finite lifespan. The ability to source these replacement parts quickly and affordably is absolutely essential to keeping a production line running. A prolonged shutdown while waiting for a critical part can be financially devastating.

Recognizing this, established Chinese suppliers have developed sophisticated global logistics for spare parts. They maintain a detailed inventory of all components for the machines they sell. Because they manufacture at scale, the cost of these parts is often significantly lower than for comparable European or North American machines. They have streamlined their export processes to ship parts by air freight to anywhere in the world, often within a matter of days. Before purchasing a block making machine, a serious buyer should inquire about the manufacturer’s spare parts policy, 可用性, and typical delivery times to their region. A reliable supply chain for spare parts is a non-negotiable component of a successful long-term operation.

Building a Long-Term Partnership

最終的に, the decision to purchase a China brick making machine should be viewed as the beginning of a relationship. The manufacturer’s role extends beyond the point of sale. Their interest lies in seeing your business succeed, as your success becomes a case study and a testament to the quality of their equipment. This partnership perspective is a hallmark of the best companies in the industry. They are responsive to feedback, provide ongoing advice, and may even inform you of new upgrades or mold designs that could benefit your operation. By choosing a manufacturer that is committed to this kind of long-term partnership, you are not just buying a piece of steel; you are gaining an ally in the global construction materials industry.

よくある質問 (よくある質問)

What is the primary difference between a concrete block machine and a fly ash brick machine? The primary difference lies in the raw materials and the curing process. A concrete block making machine typically uses cement, 砂, and gravel, and the blocks cure naturally over time. あ China fly ash brick making machine uses fly ash (a byproduct of coal power plants), 砂または石のほこり, and a binder like cement or lime. These bricks often require steam curing in an autoclave to achieve their final strength, resulting in a lighter, more insulating product.

How much space do I need to install a fully automatic block machine production line? A complete production line requires significant space. You must account for the main machine, the mixer, the cement silo, aggregate batching system, the block conveyor, and a curing area. A typical layout for a medium-to-large scale fully automatic block machine line might require a workshop area of 600-1500 平方メートル, plus a large outdoor yard for raw material storage and final product curing and storage.

Can one machine produce both hollow blocks and pavers? はい, absolutely. The versatility to produce different types of blocks is a key feature. By purchasing and installing different mold sets, a single base machine can function as a hollow block machine, a solid block machine, or a paver block machine. The changeover process typically takes a few hours.

What is the average lifespan of a China brick making machine? With proper maintenance and the use of high-quality components, a well-built China brick making machine can have a very long operational life. The main frame and structure are designed to last for decades. Key components like the hydraulic system and motors can last for many years, while wearable parts like molds and conveyor belts will need periodic replacement. A lifespan of 15-20 years or more is a reasonable expectation for a machine that is properly cared for.

Are financing options available for purchasing these machines? While manufacturers themselves do not typically offer direct financing, they can provide all the necessary documentation for you to secure financing from your local bank or international trade finance institutions. This includes proforma invoices, detailed technical specifications, and company credentials. Some international trade agreements or export-import banks may also offer programs to facilitate such purchases.

What are the main raw materials needed to make concrete blocks? The fundamental ingredients are quite simple. The primary binder is Portland cement, which reacts with water to harden and bind the other materials together. The main structural component is aggregate, which is a mix of sand and small crushed stone or gravel. Water is the third ingredient, needed to activate the cement. The exact ratio of these components will vary depending on the desired strength and type of block being produced.

How do I choose a reliable manufacturer? Choosing a reliable manufacturer involves several steps. Look for companies with a long history and a strong international presence. Verify their ISO 9001 and CE certifications. Ask for references from customers in your region. Evaluate their communication and technical support. A reputable manufacturer will be transparent, knowledgeable, and focused on building a long-term relationship (reitmachine.com).

結論

The decision to invest in a new block production line is a defining moment for any construction materials business. It is a choice that will shape the company’s production capacity, 製品品質, and financial health for years to come. A thorough and dispassionate analysis of the global market in 2025 reveals a compelling and logical case for the China brick making machine. This case is not built on the single pillar of price, but on an integrated foundation of five key strengths: a superior total cost of ownership, advanced technological integration, exceptional production versatility through customizable molds, a rigorous commitment to quality control and global standards, and the security of a comprehensive support system.

To dismiss this option based on outdated perceptions is to overlook a profound shift in global industrial manufacturing. The modern China brick making machine is a sophisticated, 信頼性のある, and highly productive piece of equipment, born from an ecosystem of intense competition and innovation. For enterprises in the United States, カナダ, ロシア, 韓国, そしてその先へ, it represents an opportunity to acquire world-class production technology in a way that is both economically rational and strategically sound. By engaging with a reputable supplier, a business is not merely buying a machine; it is investing in a powerful engine for growth and forging a partnership for long-term success.