Abstrait

The acquisition of a block making machine represents a significant capital investment for any construction or manufacturing enterprise. Cette analyse examine le cas convaincant pour s'approvisionner une machine de fabrication de brique en Chine dans le 2025 marché mondial, focusing on five principal domains of advantage: economic efficiency, technological advancement, production versatility, quality assurance, and logistical support. The study posits that Chinese manufacturers have cultivated a unique industrial ecosystem that allows them to produce technologically sophisticated equipment, such as the fully automatic block machine, at a highly competitive price point. This is achieved not through a compromise in quality, but through economies of scale, mature supply chains, and intense domestic competition. A nuanced evaluation reveals that the value proposition extends beyond the initial purchase price to encompass a lower total cost of ownership, extensive customization options for products like paver blocks and hollow blocks, and robust after-sales support. For businesses in North America, L'Europe , and Asia, understanding these integrated benefits is paramount to making a strategically sound investment decision that enhances production capacity and profitability.

Principaux à retenir

- Evaluate the total cost of ownership, not just the initial price, for a better investment.

- Modern China brick making machine models often incorporate advanced automation and technology.

- Seek manufacturers offering customization for various block types and molds.

- Verify quality control certifications and adherence to international standards.

- Confirm the availability of comprehensive after-sales service and spare parts.

- A versatile block making machine can produce concrete, creux, and paver blocks.

- Choose a reputable supplier to ensure long-term reliability and support.

Table des matières

- Raison 1: A Paradigm of Cost-Effectiveness Beyond the Initial Price Tag

- Raison 2: Advanced Manufacturing and Technological Sophistication

- Raison 3: Unrivaled Customization and Production Versatility

- Raison 4: The Assurance of Robust Quality Control and Global Standards

- Raison 5: Streamlined Supply Chains and Comprehensive Support Systems

Raison 1: A Paradigm of Cost-Effectiveness Beyond the Initial Price Tag

When a business considers the procurement of heavy industrial equipment, the conversation often begins with price. Encore, a fixation on the initial invoice figure can obscure a more profound economic reality. What, alors, constitutes true value in a significant piece of industrial equipment like a block making machine? The argument for the economic superiority of a China brick making machine rests not on a simple claim of being “cheaper,” but on a comprehensive understanding of the total cost of ownership (Coût total de possession), a concept that encompasses every expense incurred throughout the machine’s operational life. Chinese manufacturing, particularly in specialized sectors like construction machinery, has achieved a level of efficiency that allows for a re-evaluation of what is possible within a given capital budget.

Analyzing the Total Cost of Ownership

The initial purchase price is merely the entry point. A thoughtful investor must project forward, considering the financial landscape of the machine’s entire lifecycle. This includes operational costs, such as energy consumption and labor requirements. It also includes maintenance expenses, which cover routine servicing and the replacement of wearable parts. Pour terminer, il faut tenir compte de la productivité et de la durée de vie de la machine, qui déterminent en fin de compte le retour sur investissement.

Une machine moderne de fabrication de briques en Chine est souvent conçue en tenant compte de ces principes de coût total de possession.. Par exemple, de nombreux modèles sont équipés de systèmes hydrauliques et de moteurs économes en énergie, ce qui peut générer des économies substantielles sur les factures d’électricité au fil des années de fonctionnement. De la même manière, l'évolution vers l'automatisation, une marque du contemporain machine à blocs entièrement automatique, réduit le recours au travail manuel. Cela réduit non seulement les dépenses salariales, mais atténue également le risque d'erreur humaine., conduisant à une qualité de produit plus constante et à moins de gaspillage de matériaux. Lorsque vous comparez ces économies à long terme à la mise de fonds initiale, la logique économique devient exceptionnellement claire. Le coût initial inférieur agit comme un catalyseur, enabling a faster path to profitability.

The Economics of Scale in Chinese Manufacturing

How is it possible for manufacturers to offer such advanced machinery at these price points? The answer lies in the vast, interconnected industrial ecosystem of China. Decades of focused development have created an environment where economies of scale are not just a textbook concept but a daily reality. Manufacturers of the concrete block making machine benefit from a highly developed domestic supply chain. Everything from the raw steel used in the frame, to the hydraulic pumps, to the programmable logic controllers (Automates) that form the machine’s brain, can be sourced from specialized, efficace, and geographically proximate suppliers.

This proximity and scale reduce procurement costs, minimize transportation overhead, and shorten production timelines. L’intense concurrence nationale stimule l’innovation et pousse les fabricants à optimiser continuellement leurs processus.. Pour un acheteur international aux États-Unis, Canada, ou la Russie, cet écosystème se traduit directement par un prix plus accessible pour une machine de fabrication de blocs de haute qualité. Tu es, en vigueur, bénéficiant d’un niveau d’optimisation industrielle difficilement reproductible ailleurs dans le monde.

Naviguer dans les tarifs et l'expédition pour des économies maximales

Pour tout achat international, les coûts de logistique et les droits d'importation sont une considération sérieuse. Une analyse prudente nécessite de les prendre en compte dans le coût final au débarquement.. Les fournisseurs chinois réputés possèdent une vaste expérience dans la logistique mondiale. Ils ont établi des relations avec des transporteurs maritimes et des courtiers en douane, leur permettant de naviguer efficacement dans les complexités du commerce international. Ils peuvent souvent fournir des informations précises, des devis tout compris qui évitent les dépenses imprévues.

Même si les tarifs peuvent fluctuer en fonction de facteurs géopolitiques, les fabricants expérimentés peuvent fournir des conseils sur un système harmonisé (SH) codes et documentation pour garantir le dédouanement le plus fluide possible. En travaillant avec un fournisseur compétent, une entreprise peut gérer efficacement ces coûts variables, préserver l'avantage économique inhérent à l'achat d'une machine de fabrication de briques en Chine. L’objectif est de transformer un défi logistique potentiellement intimidant en un élément prévisible de la stratégie d’investissement globale..

Raison 2: Advanced Manufacturing and Technological Sophistication

Une perception courante, mais dépassée, de l’industrie manufacturière chinoise est celle d’une simple réplication plutôt que d’une véritable innovation.. This view fails to recognize the profound transformation that has occurred over the past two decades. Aujourd'hui, the leading manufacturers of construction equipment are not just participants in the global market; they are drivers of technological progress. The contemporary China brick making machine is a testament to this evolution, often incorporating features and automation levels that rival or exceed those of their Western counterparts. Examining the technological heart of these machines reveals a commitment to precision, Efficacité, and intelligent operation.

The Role of Automation and PLC Systems

At the core of a modern block production line is the Programmable Logic Controller (API). Think of the PLC as the central nervous system of the machine. Il s'agit d'un ordinateur industriel robuste qui orchestre chaque action avec une précision de l'ordre de la microseconde : depuis la mesure exacte et le mélange des matières premières comme le ciment et les granulats jusqu'à la fréquence de vibration du moule et l'empilement final des blocs finis..

Les principaux fabricants chinois intègrent des systèmes PLC sophistiqués de marques mondialement reconnues comme Siemens ou Mitsubishi., en les associant à des interfaces homme-machine intuitives à écran tactile (IHM). Cela permet à un opérateur de surveiller l’ensemble du processus de production en temps réel, ajuster les paramètres d'un simple toucher, et diagnostiquer tout problème potentiel avant qu'il ne se transforme en panne critique. Une machine à blocs entièrement automatique, guidé par un tel système, peut fonctionner en continu avec une intervention humaine minimale. Ce niveau d'automatisation n'est plus un luxe; it is a fundamental feature that ensures unparalleled consistency, maximise le rendement, and enhances workplace safety. It is the technological engine that turns raw materials into high-quality building components with remarkable efficiency.

Innovations in Vibration and Hydraulic Technology

The quality of a concrete block—its density, force, and finish—is largely determined by the process of compaction and vibration. This is where the raw materials are pressed into the mold and consolidated into a solid unit. It is an area where Chinese engineering has made significant strides. Advanced systems now utilize synchronized table and tamper head vibration, driven by powerful, frequency-controlled motors.

This technology allows for the precise application of vibrational force, ensuring that the concrete mixture is evenly distributed and compacted throughout the mold. The result is a block with fewer voids, higher compressive strength, and sharper, more defined edges. Paired with high-performance hydraulic systems, which provide the immense pressure needed for compaction, this advanced vibration technology is what separates a superior block from a mediocre one. A machine capable of this, such as a specialized paver block machine, can produce high-density interlocking pavers that can withstand heavy traffic and harsh weather conditions for decades.

A Comparative Look at Automation Levels

To better understand the options available, it is helpful to categorize the machines based on their degree of automation. This allows a business to align its investment with its specific production needs, disponibilité de la main d'œuvre, et budget.

| Fonctionnalité | Machine manuelle | Machine semi-automatique | Machine à blocs entièrement automatique |

|---|---|---|---|

| Opération | À forte intensité de main d'œuvre; nécessite plusieurs opérateurs pour l’alimentation du matériau, pressage, et démoulage. | Mélange de processus automatisés et d'intervention manuelle; l'opérateur gère les étapes clés via des leviers ou des boutons. | Contrôlé par PLC; surveillance humaine minimale requise depuis l'entrée des matières premières jusqu'à l'empilage final des blocs. |

| Capacité de sortie | Faible (Par exemple, 1,000-2,000 blocs/jour) | Moyen (Par exemple, 5,000-15,000 blocs/jour) | Haut à très haut (Par exemple, 20,000+ blocs/jour) |

| Cohérence | Dépend fortement de la compétence de l'opérateur; potentiel de variation significative. | Bonne consistance grâce aux cycles de pressage et de vibration automatisés. | Excellente consistance; chaque bloc est produit exactement selon les mêmes spécifications. |

| Coût de la main d'œuvre | Élevé par unité produite | Modéré | Faible par unité produite |

| Investissement initial | Faible | Moyen | Haut |

| Idéal pour | Startups à petite échelle, projets communautaires, ou zones avec des coûts de main d'œuvre très faibles. | Petites et moyennes entreprises (PME) cherche à augmenter la production. | Opérations commerciales à grande échelle, major construction projects, established manufacturers. |

This table illustrates a clear trade-off. While a manual machine has the lowest entry cost, un machine à blocs entièrement automatique offers vastly superior efficiency, cohérence, and long-term profitability for any serious commercial venture.

Raison 3: Unrivaled Customization and Production Versatility

Dans un marché concurrentiel, the ability to adapt and diversify one’s product offerings is a powerful advantage. A construction material business may need to produce standard building blocks one day, decorative pavers the next, and specialized hollow blocks the day after. The capacity to meet these varied demands with a single piece of capital equipment is a defining feature of a wise investment. Chinese manufacturers excel in this domain, offering a degree of customization and versatility that empowers businesses to be agile and responsive to market needs. Cette flexibilité n’est pas une réflexion après coup; il est intégré à la conception même de l'équipement.

La puissance des moules interchangeables

Le véritable génie d'une machine de fabrication de blocs moderne réside dans sa conception modulaire, spécifiquement le système de moules interchangeables. Le corps principal de la machine : le châssis, la presse hydraulique, le système de vibration – est une plate-forme universelle. Le produit spécifique qu'il crée est entièrement déterminé par le jeu de moules installé. Une seule machine de fabrication de briques en Chine peut, donc, être un pôle de production polyvalent.

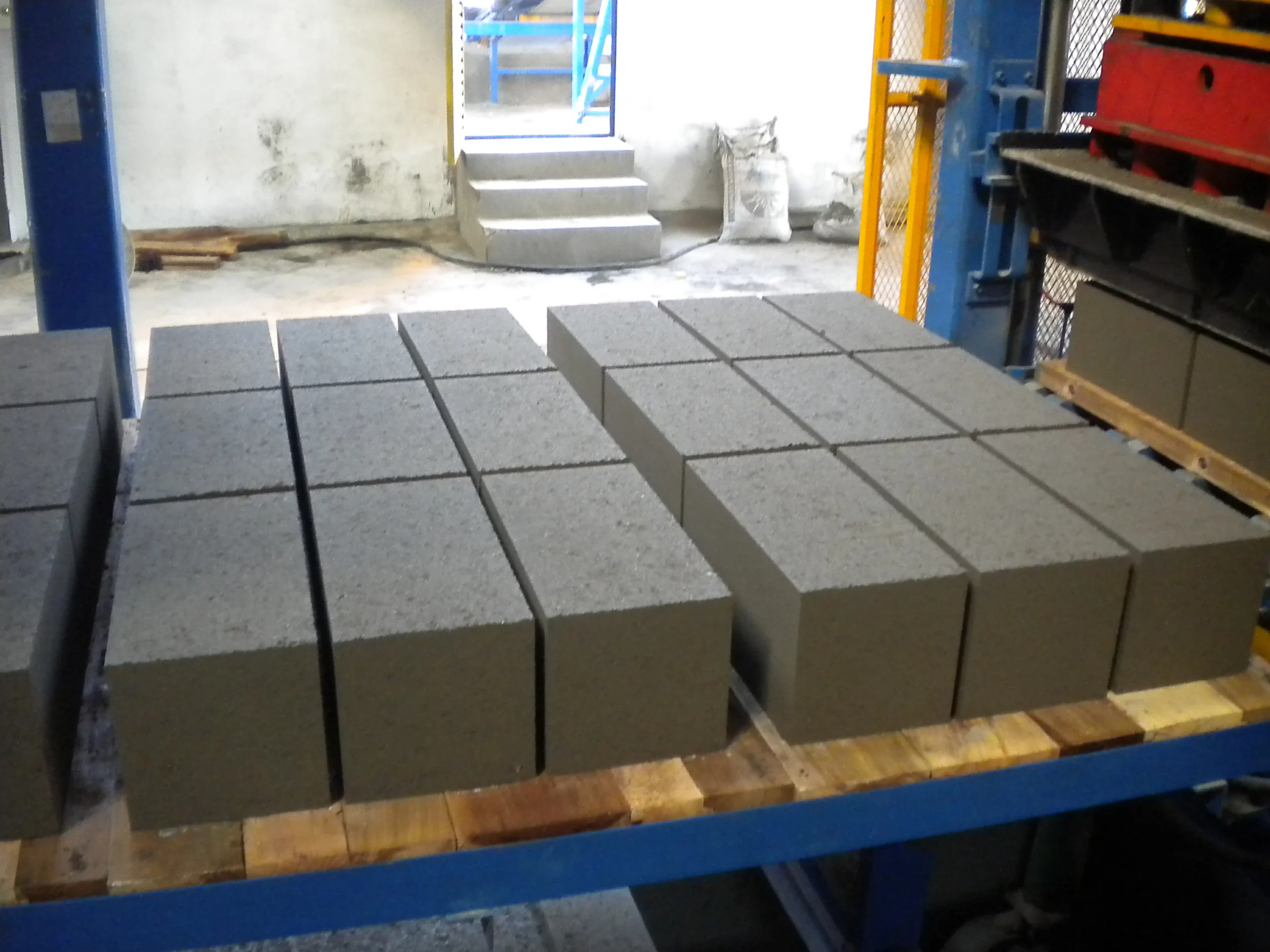

Imaginez les possibilités. Avec un jeu de moules, vous pouvez produire des blocs de béton porteurs à haute résistance pour les murs porteurs. En passant quelques heures à changer le moule, la même machine peut être transformée en machine à blocs creux, producing lighter units ideal for partition walls and insulation. Another mold change, and you now have a paver block machine, capable of manufacturing intricate, interlocking paving stones for driveways, terrasses, et espaces publics. This capability is liberating. It means a business is not locked into a single product line. It can pivot its production based on client orders, seasonal demand, or emerging architectural trends. Reputable manufacturers offer a vast catalog of standard mold designs and, crucially, provide custom mold fabrication services based on a client’s specific drawings or requirements.

Producing a Spectrum of Block Types

The versatility extends beyond just shape. A well-designed machine allows for precise control over the raw material mix and compaction parameters. This enables the production of a wide array of concrete products with different properties.

- Solid Concrete Blocks: The backbone of construction, used for foundations and load-bearing walls. The machine must provide immense compaction force to ensure maximum density and strength.

- Blocs creux: These contain one or more large voids. They are lighter, easier to handle, and offer better thermal and acoustic insulation. A hollow block machine must ensure consistent wall thickness and sharp core definitions.

- Pavés autobloquants: These require high aesthetic quality, precise dimensions for a tight fit, and exceptional surface durability to withstand abrasion and weathering. A paver block machine uses specialized vibration patterns to achieve a dense, smooth top layer.

- Curbstones and Slabs: Plus grand, heavier units used for landscaping and infrastructure. The machine needs a robust frame and a powerful feeding system to handle the larger volume of material required for each cycle.

- Briques de cendres volantes: An environmentally conscious option that utilizes industrial waste. The process for making fly ash bricks requires different mix proportions and curing methods, which a versatile machine can accommodate. Explorer sustainable building solutions can open up new markets and government incentives.

The ability to produce this entire spectrum from a single production line fundamentally changes a business’s market position, turning it from a simple supplier into a comprehensive building solutions provider.

Comparing Material Properties for Different Applications

The choice of block type is dictated by its intended use. Understanding the material science behind these choices is key for any producer. The machine’s role is to reliably and consistently create products that meet these specifications.

| Property | Bloc en béton standard | Fly Ash Brick | Hollow Concrete Block |

|---|---|---|---|

| Primary Raw Materials | Ciment, Le sable, Aggregate (Gravier) | Cendres volantes, Sand/Stone Dust, Cement/Lime | Ciment, Le sable, Aggregate (Gravier) |

| Résistance à la compression | Haut (Typiquement 15-30 MPa) | Moderate to High (10-25 MPa) | Modéré (Lower due to voids) |

| Densité | Haut (approx. 2200-2400 kg/m³) | Inférieur (approx. 1700-1900 kg/m³) | Faible (approx. 1400-1800 kg/m³) |

| Thermal Insulation | Faible | Bien | Very Good |

| Absorption d'eau | Modéré | Faible | Modéré |

| Primary Application | Load-bearing walls, fondations | Murs non porteurs, infill masonry | Cloisons de séparation, exterior non-load-bearing walls |

| Impact environnemental | Haut (due to cement production) | Faible (utilizes industrial waste) | Modéré |

A superior block making machine provides the operator with the control needed to perfect the production of each of these types, adjusting vibration, pression, and cycle times to optimize for the specific material characteristics.

Raison 4: The Assurance of Robust Quality Control and Global Standards

An investment in industrial machinery is an investment in reliability. Une machine qui souffre de pannes fréquentes, produit des produits incohérents, ou échoue prématurément n'est pas un atout mais un passif. Pour cette raison, un examen des processus de contrôle de la qualité et du respect des normes reconnues n'est pas qu'un détail technique; c'est un élément fondamental du processus de diligence raisonnable. Le discours sur l’industrie manufacturière chinoise s’est résolument orienté vers la qualité., avec des entreprises leaders mettant en œuvre des systèmes rigoureux pour garantir que leurs produits répondent aux attentes d'une clientèle mondiale exigeante. Faire confiance à un fabricant nécessite de comprendre son engagement envers l’excellence, un engagement qui doit être évident dans leurs documents, leurs processus, et leurs certifications.

Des matières premières à l’assemblage final

La qualité ne peut pas être inspectée dans un produit à la fin; it must be built in from the very beginning. For a block making machine, this principle starts with the selection of raw materials. A reputable manufacturer will use high-strength, certified steel (such as Q235 or manganese steel) for the machine’s main frame to ensure it can withstand the immense, repetitive stresses of hydraulic pressure and vibration for years without fatigue or deformation.

The scrutiny continues with key components. Systèmes hydrauliques, moteurs, bearings, and PLC controllers are often sourced from internationally respected brands or from top-tier domestic suppliers who have themselves undergone stringent quality audits. During the manufacturing process, critical steps like welding are performed by certified technicians, often using robotic welders for perfect consistency. After fabrication, key surfaces are precision-machined to ensure perfect alignment of the mold and tamper head, a detail that is essential for producing dimensionally accurate blocks. Pour terminer, the entire machine undergoes a comprehensive testing protocol before it is disassembled for shipping. This involves a no-load run to check all mechanical and electrical functions, followed by a load run where the machine actually produces blocks to verify its performance under real-world conditions. This meticulous, multi-stage approach is the bedrock of reliability.

Understanding Certifications: CE and ISO

In the world of international trade, objective, third-party certifications serve as a universal language of quality and safety. For machinery, two of the most significant are the CE mark and ISO 9001 certification.

-

Marquage CE: Le “Conformité Européenne” mark indicates that a product complies with the high safety, santé, and environmental protection standards of the European Economic Area (EEE). For a block making machine, this means the equipment has been designed to minimize electrical hazards, includes necessary safety guards to protect operators from moving parts, and is accompanied by comprehensive technical documentation. While it is a European standard, the CE mark is recognized globally as a strong indicator of a manufacturer’s commitment to safety and engineering best practices.

-

ISO 9001: This is a global standard for Quality Management Systems (QMS). A company that is ISO 9001 certified has demonstrated that it has a systematic, process-driven approach to quality. This includes everything from how it handles customer orders and designs products to how it selects suppliers and manages its production floor. It is an assurance that the manufacturer has robust, repeatable systems in place to deliver a quality product consistently. When evaluating a potential supplier for a machine de fabrication de blocs de béton, asking for their CE and ISO 9001 certificates is a crucial step.

The Importance of a Reputable Supplier

The machine itself is only part of the equation. The manufacturer behind it is equally important. A reputable supplier is a long-term partner, not just a one-time vendor. Such a supplier, like one with a legacy of engineering excellence, will have a track record of successful installations in various countries, including demanding markets like the United States, Canada, et la Corée du Sud. They will be transparent about their processes, willing to provide detailed technical specifications, and able to offer references from past clients.

A reputable supplier understands that their success is tied to your success. They invest in their reputation by investing in the quality of their products and the satisfaction of their customers. They provide clear communication, realistic delivery timelines, and stand behind their product with a solid warranty. Choosing such a partner transforms the purchase from a simple transaction into a strategic alliance aimed at building your business’s production capabilities.

Raison 5: Streamlined Supply Chains and Comprehensive Support Systems

The operational life of a block making machine begins the moment it is delivered. Its long-term value is profoundly influenced by the support structure that accompanies it. A technologically advanced and well-built machine can be rendered ineffective without proper installation, entraînement, and a reliable source for spare parts and technical assistance. The most forward-thinking Chinese manufacturers have recognized that providing a superior product is only half the battle. They have invested heavily in creating comprehensive support systems and leveraging their logistical expertise to ensure their customers can maximize the productivity and lifespan of their investment, regardless of where they are in the world.

Service après-vente: Installation, Entraînement, et support technique

The journey with a new machine should not be a solitary one. Leading manufacturers offer a suite of after-sales services designed to ensure a smooth transition and continued operational excellence.

-

Installation et mise en service: Many suppliers offer the option to send their own experienced engineers to the customer’s site. These technicians oversee the assembly of the production line, ensure all electrical and hydraulic connections are correct, and commission the machine, which involves the initial test runs to calibrate its performance for the local raw materials. This professional oversight eliminates guesswork and ensures the machine is set up for optimal performance from day one.

-

Formation des opérateurs: A machine is only as good as the person operating it. The manufacturer’s technicians will provide hands-on training for the local staff. This covers the day-to-day operation of the machine via its HMI, procedures for changing molds, routine maintenance tasks like lubrication and inspection, and basic troubleshooting. This transfer of knowledge empowers the customer’s team to operate the machine confidently and efficiently.

-

Remote Technical Support: In the digital age, assistance is often just a call or a video conference away. Manufacturers provide ongoing technical support to help diagnose and resolve issues remotely. With modern PLC systems, technicians can sometimes even access the machine’s diagnostics online to identify problems quickly, minimizing downtime.

This three-pronged approach—professional installation, comprehensive training, and accessible support—forms a safety net that protects the customer’s investment.

The Global Reach of Spare Parts Logistics

Chaque machine, peu importe à quel point il est bien construit, has parts that will wear out over time. Moules, bandes transporteuses, hydraulic seals, and certain electrical components have a finite lifespan. The ability to source these replacement parts quickly and affordably is absolutely essential to keeping a production line running. A prolonged shutdown while waiting for a critical part can be financially devastating.

Recognizing this, established Chinese suppliers have developed sophisticated global logistics for spare parts. They maintain a detailed inventory of all components for the machines they sell. Because they manufacture at scale, the cost of these parts is often significantly lower than for comparable European or North American machines. They have streamlined their export processes to ship parts by air freight to anywhere in the world, often within a matter of days. Before purchasing a block making machine, a serious buyer should inquire about the manufacturer’s spare parts policy, disponibilité, and typical delivery times to their region. A reliable supply chain for spare parts is a non-negotiable component of a successful long-term operation.

Building a Long-Term Partnership

Finalement, the decision to purchase a China brick making machine should be viewed as the beginning of a relationship. The manufacturer’s role extends beyond the point of sale. Their interest lies in seeing your business succeed, as your success becomes a case study and a testament to the quality of their equipment. This partnership perspective is a hallmark of the best companies in the industry. They are responsive to feedback, provide ongoing advice, and may even inform you of new upgrades or mold designs that could benefit your operation. By choosing a manufacturer that is committed to this kind of long-term partnership, you are not just buying a piece of steel; you are gaining an ally in the global construction materials industry.

Foire aux questions (FAQ)

What is the primary difference between a concrete block machine and a fly ash brick machine? The primary difference lies in the raw materials and the curing process. A concrete block making machine typically uses cement, le sable, and gravel, and the blocks cure naturally over time. UN China fly ash brick making machine uses fly ash (un sous-produit des centrales électriques au charbon), sable ou poussière de pierre, and a binder like cement or lime. These bricks often require steam curing in an autoclave to achieve their final strength, resulting in a lighter, more insulating product.

How much space do I need to install a fully automatic block machine production line? A complete production line requires significant space. You must account for the main machine, the mixer, the cement silo, aggregate batching system, the block conveyor, and a curing area. A typical layout for a medium-to-large scale fully automatic block machine line might require a workshop area of 600-1500 mètres carrés, plus a large outdoor yard for raw material storage and final product curing and storage.

Can one machine produce both hollow blocks and pavers? Oui, absolument. The versatility to produce different types of blocks is a key feature. By purchasing and installing different mold sets, a single base machine can function as a hollow block machine, a solid block machine, ou une machine à pavés. The changeover process typically takes a few hours.

What is the average lifespan of a China brick making machine? With proper maintenance and the use of high-quality components, a well-built China brick making machine can have a very long operational life. The main frame and structure are designed to last for decades. Key components like the hydraulic system and motors can last for many years, while wearable parts like molds and conveyor belts will need periodic replacement. A lifespan of 15-20 years or more is a reasonable expectation for a machine that is properly cared for.

Are financing options available for purchasing these machines? While manufacturers themselves do not typically offer direct financing, they can provide all the necessary documentation for you to secure financing from your local bank or international trade finance institutions. This includes proforma invoices, detailed technical specifications, and company credentials. Some international trade agreements or export-import banks may also offer programs to facilitate such purchases.

What are the main raw materials needed to make concrete blocks? The fundamental ingredients are quite simple. The primary binder is Portland cement, which reacts with water to harden and bind the other materials together. The main structural component is aggregate, which is a mix of sand and small crushed stone or gravel. Water is the third ingredient, needed to activate the cement. The exact ratio of these components will vary depending on the desired strength and type of block being produced.

How do I choose a reliable manufacturer? Choosing a reliable manufacturer involves several steps. Look for companies with a long history and a strong international presence. Verify their ISO 9001 and CE certifications. Ask for references from customers in your region. Evaluate their communication and technical support. A reputable manufacturer will be transparent, bien informé, and focused on building a long-term relationship (reitmachine.com).

Conclusion

The decision to invest in a new block production line is a defining moment for any construction materials business. It is a choice that will shape the company’s production capacity, qualité du produit, and financial health for years to come. A thorough and dispassionate analysis of the global market in 2025 reveals a compelling and logical case for the China brick making machine. This case is not built on the single pillar of price, but on an integrated foundation of five key strengths: a superior total cost of ownership, advanced technological integration, exceptional production versatility through customizable molds, a rigorous commitment to quality control and global standards, and the security of a comprehensive support system.

To dismiss this option based on outdated perceptions is to overlook a profound shift in global industrial manufacturing. The modern China brick making machine is a sophisticated, fiable, and highly productive piece of equipment, born from an ecosystem of intense competition and innovation. For enterprises in the United States, Canada, Russie, Corée du Sud, et au-delà, it represents an opportunity to acquire world-class production technology in a way that is both economically rational and strategically sound. By engaging with a reputable supplier, a business is not merely buying a machine; it is investing in a powerful engine for growth and forging a partnership for long-term success.