Abstrak

Akuisisi mesin pembuat blok merupakan investasi modal yang signifikan untuk setiap perusahaan konstruksi atau manufaktur. Analisis ini meneliti kasus yang menarik untuk mencari mesin pembuat batu bata di China di 2025 Pasar Global, berfokus pada lima domain utama keuntungan: efisiensi ekonomi, kemajuan teknologi, fleksibilitas produksi, jaminan kualitas, dan dukungan logistik. Studi ini berpendapat bahwa pabrikan Tiongkok telah mengembangkan ekosistem industri unik yang memungkinkan mereka memproduksi peralatan berteknologi canggih, seperti mesin blok yang sepenuhnya otomatis, pada titik harga yang sangat kompetitif. Hal ini dicapai bukan melalui kompromi dalam kualitas, namun melalui skala ekonomi, rantai pasokan yang matang, dan persaingan domestik yang ketat. Evaluasi yang berbeda mengungkapkan bahwa proposisi nilai melampaui harga pembelian awal dan mencakup total biaya kepemilikan yang lebih rendah, pilihan penyesuaian yang luas untuk produk seperti paver block dan hollow block, dan dukungan purna jual yang kuat. Untuk bisnis di Amerika Utara, Eropa, dan Asia, memahami manfaat terpadu ini sangat penting untuk membuat keputusan investasi yang strategis dan meningkatkan kapasitas produksi dan profitabilitas.

Kunci takeaways

- Evaluasi total biaya kepemilikan, bukan hanya harga awal, untuk investasi yang lebih baik.

- Model mesin pembuat batu bata Tiongkok modern sering kali menggunakan otomatisasi dan teknologi canggih.

- Carilah produsen yang menawarkan penyesuaian untuk berbagai jenis balok dan cetakan.

- Verifikasi sertifikasi kontrol kualitas dan kepatuhan terhadap standar internasional.

- Konfirmasikan ketersediaan layanan purna jual dan suku cadang yang komprehensif.

- Mesin pembuat balok serbaguna dapat menghasilkan beton, kosong, dan blok paver.

- Pilih pemasok yang memiliki reputasi baik untuk memastikan keandalan dan dukungan jangka panjang.

Daftar isi

- Alasan 1: Paradigma Efektivitas Biaya Melampaui Label Harga Awal

- Alasan 2: Manufaktur Maju dan Kecanggihan Teknologi

- Alasan 3: Kustomisasi dan Keserbagunaan Produksi yang Tak Tertandingi

- Alasan 4: Jaminan Kontrol Kualitas yang Kuat dan Standar Global

- Alasan 5: Rantai Pasokan yang Efisien dan Sistem Pendukung yang Komprehensif

Alasan 1: Paradigma Efektivitas Biaya Melampaui Label Harga Awal

Ketika sebuah bisnis mempertimbangkan pengadaan alat industri berat, percakapan sering kali dimulai dengan harga. Belum, fiksasi pada angka tagihan awal dapat mengaburkan realitas ekonomi yang lebih mendalam. Apa, Kemudian, merupakan nilai sebenarnya dalam peralatan industri penting seperti mesin pembuat blok? Argumen mengenai keunggulan ekonomi mesin pembuat batu bata di Tiongkok tidak hanya didasarkan pada klaim sederhana “lebih murah,” tetapi berdasarkan pemahaman komprehensif tentang total biaya kepemilikan (Tco), sebuah konsep yang mencakup setiap biaya yang dikeluarkan sepanjang masa operasional alat berat. manufaktur Cina, khususnya di sektor khusus seperti mesin konstruksi, telah mencapai tingkat efisiensi yang memungkinkan dilakukannya evaluasi ulang terhadap apa yang mungkin dilakukan dalam anggaran modal tertentu.

Menganalisis Total Biaya Kepemilikan

Harga pembelian awal hanyalah titik masuk. Seorang investor yang bijaksana harus memproyeksikan ke depan, mempertimbangkan lanskap keuangan seluruh siklus hidup mesin. Ini termasuk biaya operasional, seperti konsumsi energi dan kebutuhan tenaga kerja. Ini juga termasuk biaya pemeliharaan, yang mencakup servis rutin dan penggantian suku cadang yang dapat dipakai. Akhirnya, kita harus memperhitungkan produktivitas dan masa pakai alat berat, yang pada akhirnya menentukan laba atas investasi.

Mesin pembuat batu bata Tiongkok modern sering kali dirancang dengan mempertimbangkan prinsip-prinsip TCO ini. Sebagai contoh, banyak model menampilkan sistem dan motor hidrolik hemat energi, yang dapat menghasilkan penghematan besar pada tagihan listrik selama bertahun-tahun beroperasi. Demikian pula, pergerakan menuju otomatisasi, ciri khas masa kini mesin blok sepenuhnya otomatis, mengurangi ketergantungan pada tenaga kerja manual. Hal ini tidak hanya menurunkan biaya penggajian tetapi juga mengurangi risiko kesalahan manusia, menghasilkan kualitas produk yang lebih konsisten dan lebih sedikit pemborosan bahan. Bila Anda membandingkan tabungan jangka panjang ini dengan pengeluaran modal awal, logika ekonomi menjadi sangat jelas. Biaya awal yang lebih rendah bertindak sebagai katalis, memungkinkan jalur yang lebih cepat menuju profitabilitas.

Skala Ekonomi dalam Manufaktur Tiongkok

Bagaimana mungkin produsen menawarkan mesin canggih seperti itu pada titik harga seperti ini? Jawabannya terletak pada luasnya, ekosistem industri yang saling berhubungan di Tiongkok. Pembangunan yang terfokus selama berpuluh-puluh tahun telah menciptakan lingkungan di mana skala ekonomi tidak hanya sekedar konsep yang ada di buku teks, namun menjadi kenyataan sehari-hari. Produsen mesin pembuat balok beton mendapat manfaat dari rantai pasokan dalam negeri yang sangat maju. Semuanya dari baja mentah yang digunakan dalam rangka, ke pompa hidrolik, ke pengontrol logika yang dapat diprogram (PLC) yang membentuk otak mesin, dapat bersumber dari spesialis, efisien, dan pemasok yang dekat secara geografis.

Kedekatan dan skala ini mengurangi biaya pengadaan, meminimalkan overhead transportasi, dan mempersingkat jadwal produksi. The intense domestic competition further drives innovation and pressures manufacturers to optimize their processes continually. For an international buyer in the United States, Kanada, atau Rusia, this ecosystem translates directly into a more accessible price for a high-quality block making machine. You are, in effect, benefiting from a level of industrial optimization that is difficult to replicate elsewhere in the world.

Navigating Tariffs and Shipping for Maximum Savings

For any international procurement, the costs of logistics and import duties are a serious consideration. A prudent analysis requires factoring these into the final landed cost. Reputable Chinese suppliers have extensive experience in global logistics. They have established relationships with shipping carriers and customs brokers, allowing them to navigate the complexities of international trade efficiently. They can often provide accurate, all-inclusive quotes that prevent unforeseen expenses.

While tariffs can fluctuate based on geopolitical factors, experienced manufacturers can provide guidance on harmonized system (HS) codes and documentation to ensure the smoothest possible customs clearance. By working with a knowledgeable supplier, a business can effectively manage these variable costs, preserving the inherent economic advantage of sourcing a China brick making machine. The goal is to transform a potentially daunting logistical challenge into a predictable component of the overall investment strategy.

Alasan 2: Manufaktur Maju dan Kecanggihan Teknologi

A common yet outdated perception of Chinese manufacturing is one of simple replication rather than genuine innovation. This view fails to recognize the profound transformation that has occurred over the past two decades. Hari ini, the leading manufacturers of construction equipment are not just participants in the global market; they are drivers of technological progress. The contemporary China brick making machine is a testament to this evolution, often incorporating features and automation levels that rival or exceed those of their Western counterparts. Examining the technological heart of these machines reveals a commitment to precision, efisiensi, and intelligent operation.

The Role of Automation and PLC Systems

At the core of a modern block production line is the Programmable Logic Controller (PLC). Think of the PLC as the central nervous system of the machine. It is a ruggedized industrial computer that orchestrates every action with microsecond precision—from the exact measurement and mixing of raw materials like cement and aggregate to the vibration frequency of the mold and the final stacking of the finished blocks.

Leading Chinese manufacturers integrate sophisticated PLC systems from globally recognized brands like Siemens or Mitsubishi, pairing them with intuitive touchscreen human-machine interfaces (HMI). This allows an operator to monitor the entire production process in real-time, adjust parameters with a simple touch, and diagnose any potential issues before they become critical failures. A fully automatic block machine, guided by such a system, can operate continuously with minimal human intervention. This level of automation is no longer a luxury; it is a fundamental feature that ensures unparalleled consistency, memaksimalkan keluaran, and enhances workplace safety. It is the technological engine that turns raw materials into high-quality building components with remarkable efficiency.

Innovations in Vibration and Hydraulic Technology

The quality of a concrete block—its density, kekuatan, and finish—is largely determined by the process of compaction and vibration. This is where the raw materials are pressed into the mold and consolidated into a solid unit. It is an area where Chinese engineering has made significant strides. Advanced systems now utilize synchronized table and tamper head vibration, driven by powerful, frequency-controlled motors.

This technology allows for the precise application of vibrational force, ensuring that the concrete mixture is evenly distributed and compacted throughout the mold. The result is a block with fewer voids, higher compressive strength, and sharper, more defined edges. Paired with high-performance hydraulic systems, which provide the immense pressure needed for compaction, this advanced vibration technology is what separates a superior block from a mediocre one. A machine capable of this, such as a specialized paver block machine, can produce high-density interlocking pavers that can withstand heavy traffic and harsh weather conditions for decades.

A Comparative Look at Automation Levels

To better understand the options available, it is helpful to categorize the machines based on their degree of automation. This allows a business to align its investment with its specific production needs, labor availability, and budget.

| Fitur | Mesin manual | Mesin semi-otomatis | Mesin Blok Sepenuhnya Otomatis |

|---|---|---|---|

| Operasi | Labor-intensive; requires multiple operators for material feeding, mendesak, dan demolding. | Mix of automated processes and manual intervention; operator manages key steps via levers or buttons. | PLC-controlled; minimal human oversight required from raw material input to final block stacking. |

| Output Capacity | Rendah (MISALNYA., 1,000-2,000 blok/hari) | Sedang (MISALNYA., 5,000-15,000 blok/hari) | Tinggi hingga sangat tinggi (MISALNYA., 20,000+ blok/hari) |

| Konsistensi | Highly dependent on operator skill; potential for significant variation. | Good consistency due to automated pressing and vibration cycles. | Excellent consistency; every block is produced to the exact same specifications. |

| Labor Cost | High per unit produced | Sedang | Low per unit produced |

| Investasi awal | Rendah | Sedang | Tinggi |

| Ideal Untuk | Startup skala kecil, Proyek Komunitas, or areas with very low labor costs. | Usaha kecil dan menengah (UKM) looking to scale up production. | Large-scale commercial operations, major construction projects, established manufacturers. |

This table illustrates a clear trade-off. While a manual machine has the lowest entry cost, A mesin blok sepenuhnya otomatis offers vastly superior efficiency, konsistensi, and long-term profitability for any serious commercial venture.

Alasan 3: Kustomisasi dan Keserbagunaan Produksi yang Tak Tertandingi

In a competitive market, the ability to adapt and diversify one’s product offerings is a powerful advantage. A construction material business may need to produce standard building blocks one day, decorative pavers the next, and specialized hollow blocks the day after. The capacity to meet these varied demands with a single piece of capital equipment is a defining feature of a wise investment. Chinese manufacturers excel in this domain, offering a degree of customization and versatility that empowers businesses to be agile and responsive to market needs. This flexibility is not an afterthought; it is engineered into the very design of the equipment.

The Power of Interchangeable Molds

The true genius of a modern block making machine lies in its modular design, specifically the system of interchangeable molds. The main body of the machine—the frame, the hydraulic press, the vibration system—is a universal platform. The specific product it creates is determined entirely by the mold set that is installed. A single China brick making machine can, Karena itu, be a multi-purpose production hub.

Imagine the possibilities. With one mold set, you can produce high-strength load-bearing concrete blocks for structural walls. By spending a few hours to swap out the mold, the same machine can be transformed into a hollow block machine, producing lighter units ideal for partition walls and insulation. Another mold change, and you now have a paver block machine, capable of manufacturing intricate, interlocking paving stones for driveways, teras, dan ruang publik. This capability is liberating. It means a business is not locked into a single product line. It can pivot its production based on client orders, seasonal demand, or emerging architectural trends. Reputable manufacturers offer a vast catalog of standard mold designs and, crucially, provide custom mold fabrication services based on a client’s specific drawings or requirements.

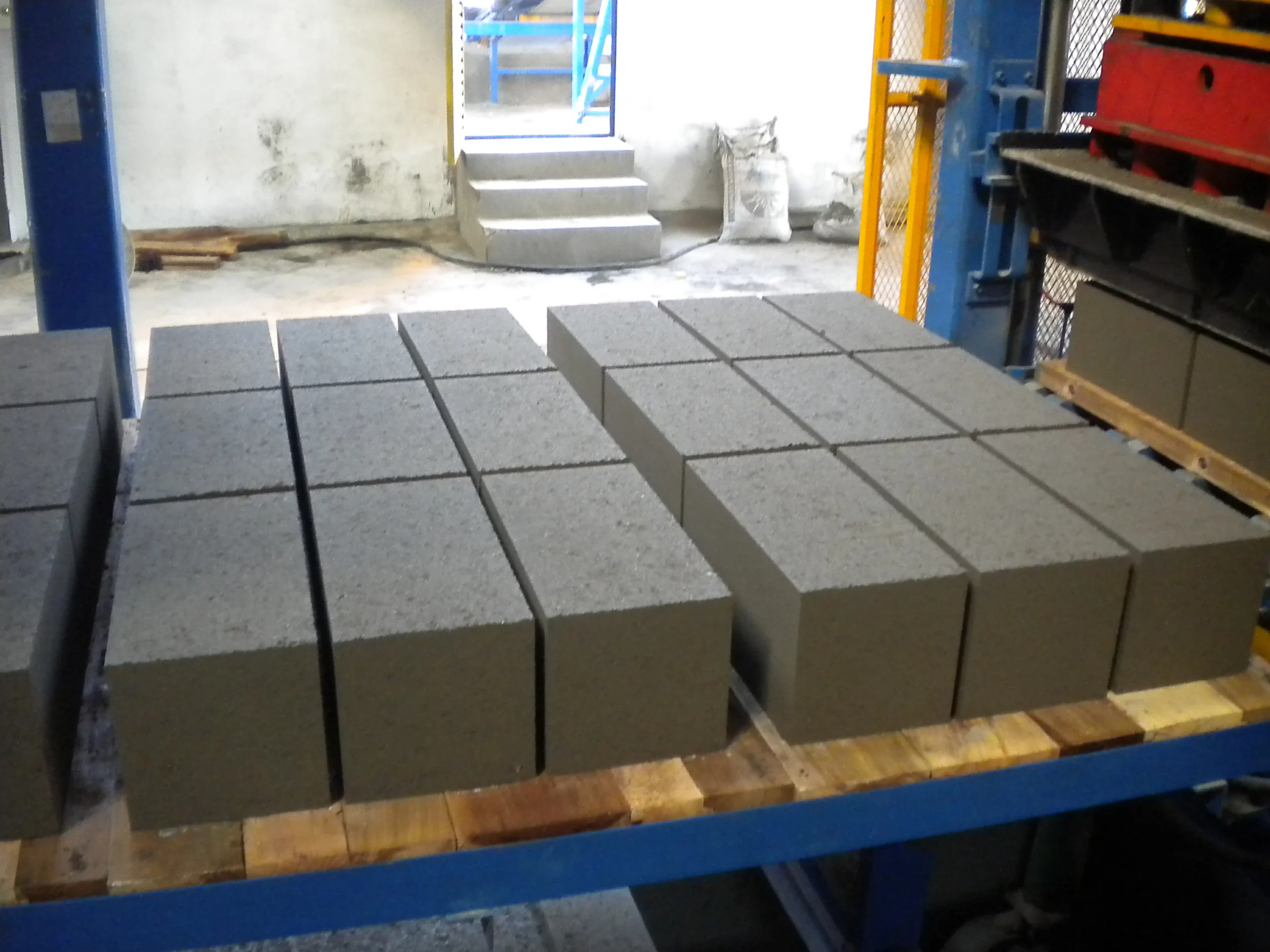

Producing a Spectrum of Block Types

The versatility extends beyond just shape. A well-designed machine allows for precise control over the raw material mix and compaction parameters. This enables the production of a wide array of concrete products with different properties.

- Solid Concrete Blocks: The backbone of construction, used for foundations and load-bearing walls. The machine must provide immense compaction force to ensure maximum density and strength.

- Blok Berongga: These contain one or more large voids. They are lighter, easier to handle, and offer better thermal and acoustic insulation. A hollow block machine must ensure consistent wall thickness and sharp core definitions.

- Pavers yang saling mengunci: These require high aesthetic quality, precise dimensions for a tight fit, and exceptional surface durability to withstand abrasion and weathering. A paver block machine uses specialized vibration patterns to achieve a dense, smooth top layer.

- Curbstones and Slabs: Lebih besar, heavier units used for landscaping and infrastructure. The machine needs a robust frame and a powerful feeding system to handle the larger volume of material required for each cycle.

- Batu bata fly ash: An environmentally conscious option that utilizes industrial waste. The process for making fly ash bricks requires different mix proportions and curing methods, which a versatile machine can accommodate. Menjelajahi sustainable building solutions can open up new markets and government incentives.

The ability to produce this entire spectrum from a single production line fundamentally changes a business’s market position, turning it from a simple supplier into a comprehensive building solutions provider.

Comparing Material Properties for Different Applications

The choice of block type is dictated by its intended use. Understanding the material science behind these choices is key for any producer. The machine’s role is to reliably and consistently create products that meet these specifications.

| Property | Blok beton standar | Fly Ash Brick | Hollow Concrete Block |

|---|---|---|---|

| Primary Raw Materials | Semen, Pasir, Agregat (Kerikil) | Fly ash, Sand/Stone Dust, Cement/Lime | Semen, Pasir, Agregat (Kerikil) |

| Kekuatan Tekan | Tinggi (Khas 15-30 MPa) | Moderate to High (10-25 MPa) | Sedang (Lower due to voids) |

| Kepadatan | Tinggi (approx. 2200-2400 kg/m³) | Lebih rendah (approx. 1700-1900 kg/m³) | Rendah (approx. 1400-1800 kg/m³) |

| Thermal Insulation | Rendah | Bagus | Very Good |

| Penyerapan Air | Sedang | Rendah | Sedang |

| Primary Application | Load-bearing walls, yayasan | Dinding tanpa beban, infill masonry | Dinding partisi, exterior non-load-bearing walls |

| Dampak Lingkungan | Tinggi (due to cement production) | Rendah (utilizes industrial waste) | Sedang |

A superior block making machine provides the operator with the control needed to perfect the production of each of these types, adjusting vibration, tekanan, and cycle times to optimize for the specific material characteristics.

Alasan 4: Jaminan Kontrol Kualitas yang Kuat dan Standar Global

An investment in industrial machinery is an investment in reliability. A machine that suffers from frequent breakdowns, produces inconsistent products, or fails prematurely is not an asset but a liability. Untuk alasan ini, an examination of quality control processes and adherence to recognized standards is not just a technicality; it is a fundamental part of the due diligence process. The narrative of Chinese manufacturing has shifted decisively towards a focus on quality, with leading companies implementing rigorous systems to ensure their products meet the expectations of a demanding global clientele. Placing trust in a manufacturer requires understanding their commitment to excellence, a commitment that should be evident in their materials, their processes, and their certifications.

From Raw Materials to Final Assembly

Quality cannot be inspected into a product at the end; it must be built in from the very beginning. For a block making machine, this principle starts with the selection of raw materials. A reputable manufacturer will use high-strength, certified steel (such as Q235 or manganese steel) for the machine’s main frame to ensure it can withstand the immense, repetitive stresses of hydraulic pressure and vibration for years without fatigue or deformation.

The scrutiny continues with key components. Sistem hidrolik, motor, bearings, and PLC controllers are often sourced from internationally respected brands or from top-tier domestic suppliers who have themselves undergone stringent quality audits. During the manufacturing process, critical steps like welding are performed by certified technicians, often using robotic welders for perfect consistency. After fabrication, key surfaces are precision-machined to ensure perfect alignment of the mold and tamper head, a detail that is essential for producing dimensionally accurate blocks. Akhirnya, the entire machine undergoes a comprehensive testing protocol before it is disassembled for shipping. This involves a no-load run to check all mechanical and electrical functions, followed by a load run where the machine actually produces blocks to verify its performance under real-world conditions. This meticulous, multi-stage approach is the bedrock of reliability.

Understanding Certifications: CE and ISO

In the world of international trade, objective, third-party certifications serve as a universal language of quality and safety. For machinery, two of the most significant are the CE mark and ISO 9001 certification.

-

Penandaan CE: Itu “Conformité Européenne” mark indicates that a product complies with the high safety, kesehatan, and environmental protection standards of the European Economic Area (EEA). For a block making machine, this means the equipment has been designed to minimize electrical hazards, includes necessary safety guards to protect operators from moving parts, and is accompanied by comprehensive technical documentation. While it is a European standard, the CE mark is recognized globally as a strong indicator of a manufacturer’s commitment to safety and engineering best practices.

-

ISO 9001: This is a global standard for Quality Management Systems (QMS). A company that is ISO 9001 certified has demonstrated that it has a systematic, process-driven approach to quality. This includes everything from how it handles customer orders and designs products to how it selects suppliers and manages its production floor. It is an assurance that the manufacturer has robust, repeatable systems in place to deliver a quality product consistently. When evaluating a potential supplier for a mesin pembuat balok beton, asking for their CE and ISO 9001 certificates is a crucial step.

The Importance of a Reputable Supplier

The machine itself is only part of the equation. The manufacturer behind it is equally important. A reputable supplier is a long-term partner, not just a one-time vendor. Such a supplier, like one with a legacy of engineering excellence, will have a track record of successful installations in various countries, including demanding markets like the United States, Kanada, dan Korea Selatan. They will be transparent about their processes, willing to provide detailed technical specifications, and able to offer references from past clients.

A reputable supplier understands that their success is tied to your success. They invest in their reputation by investing in the quality of their products and the satisfaction of their customers. They provide clear communication, realistic delivery timelines, and stand behind their product with a solid warranty. Choosing such a partner transforms the purchase from a simple transaction into a strategic alliance aimed at building your business’s production capabilities.

Alasan 5: Rantai Pasokan yang Efisien dan Sistem Pendukung yang Komprehensif

The operational life of a block making machine begins the moment it is delivered. Its long-term value is profoundly influenced by the support structure that accompanies it. A technologically advanced and well-built machine can be rendered ineffective without proper installation, pelatihan, and a reliable source for spare parts and technical assistance. The most forward-thinking Chinese manufacturers have recognized that providing a superior product is only half the battle. They have invested heavily in creating comprehensive support systems and leveraging their logistical expertise to ensure their customers can maximize the productivity and lifespan of their investment, regardless of where they are in the world.

Layanan purna jual: Instalasi, Pelatihan, dan Dukungan Teknis

The journey with a new machine should not be a solitary one. Leading manufacturers offer a suite of after-sales services designed to ensure a smooth transition and continued operational excellence.

-

Instalasi dan commissioning: Many suppliers offer the option to send their own experienced engineers to the customer’s site. These technicians oversee the assembly of the production line, ensure all electrical and hydraulic connections are correct, and commission the machine, which involves the initial test runs to calibrate its performance for the local raw materials. This professional oversight eliminates guesswork and ensures the machine is set up for optimal performance from day one.

-

Pelatihan Operator: A machine is only as good as the person operating it. The manufacturer’s technicians will provide hands-on training for the local staff. This covers the day-to-day operation of the machine via its HMI, procedures for changing molds, routine maintenance tasks like lubrication and inspection, and basic troubleshooting. This transfer of knowledge empowers the customer’s team to operate the machine confidently and efficiently.

-

Remote Technical Support: In the digital age, assistance is often just a call or a video conference away. Manufacturers provide ongoing technical support to help diagnose and resolve issues remotely. With modern PLC systems, technicians can sometimes even access the machine’s diagnostics online to identify problems quickly, meminimalkan waktu henti.

This three-pronged approach—professional installation, comprehensive training, and accessible support—forms a safety net that protects the customer’s investment.

The Global Reach of Spare Parts Logistics

Setiap mesin, Tidak peduli seberapa baik dibangun, has parts that will wear out over time. Cetakan, sabuk pengangkut, hydraulic seals, and certain electrical components have a finite lifespan. The ability to source these replacement parts quickly and affordably is absolutely essential to keeping a production line running. A prolonged shutdown while waiting for a critical part can be financially devastating.

Recognizing this, established Chinese suppliers have developed sophisticated global logistics for spare parts. They maintain a detailed inventory of all components for the machines they sell. Because they manufacture at scale, the cost of these parts is often significantly lower than for comparable European or North American machines. They have streamlined their export processes to ship parts by air freight to anywhere in the world, often within a matter of days. Before purchasing a block making machine, a serious buyer should inquire about the manufacturer’s spare parts policy, tersedianya, and typical delivery times to their region. A reliable supply chain for spare parts is a non-negotiable component of a successful long-term operation.

Building a Long-Term Partnership

Akhirnya, the decision to purchase a China brick making machine should be viewed as the beginning of a relationship. The manufacturer’s role extends beyond the point of sale. Their interest lies in seeing your business succeed, as your success becomes a case study and a testament to the quality of their equipment. This partnership perspective is a hallmark of the best companies in the industry. They are responsive to feedback, provide ongoing advice, and may even inform you of new upgrades or mold designs that could benefit your operation. By choosing a manufacturer that is committed to this kind of long-term partnership, you are not just buying a piece of steel; you are gaining an ally in the global construction materials industry.

Pertanyaan yang Sering Diajukan (Pertanyaan Umum)

What is the primary difference between a concrete block machine and a fly ash brick machine? The primary difference lies in the raw materials and the curing process. A concrete block making machine typically uses cement, pasir, and gravel, and the blocks cure naturally over time. A China fly ash brick making machine uses fly ash (a byproduct of coal power plants), pasir atau debu batu, and a binder like cement or lime. These bricks often require steam curing in an autoclave to achieve their final strength, resulting in a lighter, more insulating product.

How much space do I need to install a fully automatic block machine production line? A complete production line requires significant space. You must account for the main machine, the mixer, the cement silo, aggregate batching system, the block conveyor, and a curing area. A typical layout for a medium-to-large scale fully automatic block machine line might require a workshop area of 600-1500 meter persegi, plus a large outdoor yard for raw material storage and final product curing and storage.

Can one machine produce both hollow blocks and pavers? Ya, absolutely. The versatility to produce different types of blocks is a key feature. By purchasing and installing different mold sets, a single base machine can function as a hollow block machine, a solid block machine, atau mesin blok paver. The changeover process typically takes a few hours.

What is the average lifespan of a China brick making machine? With proper maintenance and the use of high-quality components, a well-built China brick making machine can have a very long operational life. The main frame and structure are designed to last for decades. Key components like the hydraulic system and motors can last for many years, while wearable parts like molds and conveyor belts will need periodic replacement. A lifespan of 15-20 years or more is a reasonable expectation for a machine that is properly cared for.

Are financing options available for purchasing these machines? While manufacturers themselves do not typically offer direct financing, they can provide all the necessary documentation for you to secure financing from your local bank or international trade finance institutions. This includes proforma invoices, detailed technical specifications, and company credentials. Some international trade agreements or export-import banks may also offer programs to facilitate such purchases.

What are the main raw materials needed to make concrete blocks? The fundamental ingredients are quite simple. The primary binder is Portland cement, which reacts with water to harden and bind the other materials together. The main structural component is aggregate, which is a mix of sand and small crushed stone or gravel. Water is the third ingredient, needed to activate the cement. The exact ratio of these components will vary depending on the desired strength and type of block being produced.

How do I choose a reliable manufacturer? Choosing a reliable manufacturer involves several steps. Look for companies with a long history and a strong international presence. Verify their ISO 9001 and CE certifications. Ask for references from customers in your region. Evaluate their communication and technical support. A reputable manufacturer will be transparent, berpengetahuan luas, and focused on building a long-term relationship (reitmachine.com).

Kesimpulan

The decision to invest in a new block production line is a defining moment for any construction materials business. It is a choice that will shape the company’s production capacity, kualitas produk, and financial health for years to come. A thorough and dispassionate analysis of the global market in 2025 reveals a compelling and logical case for the China brick making machine. This case is not built on the single pillar of price, but on an integrated foundation of five key strengths: a superior total cost of ownership, advanced technological integration, exceptional production versatility through customizable molds, a rigorous commitment to quality control and global standards, and the security of a comprehensive support system.

To dismiss this option based on outdated perceptions is to overlook a profound shift in global industrial manufacturing. The modern China brick making machine is a sophisticated, dapat diandalkan, and highly productive piece of equipment, born from an ecosystem of intense competition and innovation. For enterprises in the United States, Kanada, Rusia, Korea Selatan, dan seterusnya, it represents an opportunity to acquire world-class production technology in a way that is both economically rational and strategically sound. By engaging with a reputable supplier, a business is not merely buying a machine; it is investing in a powerful engine for growth and forging a partnership for long-term success.