Abstrak

The block machine industry is currently undergoing a significant transformation, didorong oleh prinsip pembuatan pintar. Evolusi ini menangani cabaran berterusan seperti peningkatan kos operasi, tuntutan kualiti yang ketat, and increasing environmental regulations prevalent in 2025. An examination of this shift reveals that the integration of technologies like the Industrial Internet of Things (IIoT), artificial intelligence (Ai), advanced robotics, and digital twin simulations is not merely an upgrade but a fundamental redefinition of production processes. These technologies enable a transition from reactive or preventive operational models to predictive and optimized systems. By leveraging real-time data, manufacturers of concrete blocks, penurap, and other masonry units can achieve unprecedented levels of efficiency, konsisten, dan kemampanan. The objective analysis indicates that smart manufacturing facilitates substantial reductions in material waste, penggunaan tenaga, and machine downtime, thereby directly enhancing profitability and securing a competitive advantage in a demanding global market.

Takeaways utama

- Implement IIoT sensors for predictive maintenance, slashing machine downtime by up to 50%.

- Adopt advanced robotics to automate quality control and palletizing, increasing throughput.

- Utilize AI algorithms to optimize concrete mix designs in real-time, reducing cement usage.

- Develop digital twins of your production line to simulate and perfect new products virtually.

- Foster a data-driven culture to continuously improve efficiency and sustainability.

- Embrace smart manufacturing in the block machine industry to ensure long-term profitability.

- Analyze modern fully automatic concrete block production lines to benchmark current capabilities.

Jadual Kandungan

- A New Epoch for Block Manufacturing

- 1. Integrating the Industrial Internet of Things (IIoT) for Predictive Supremacy

- 2. Advanced Automation and Robotics: From Raw Material to Palletization

- 3. AI and Machine Learning for Process Optimization and Quality Control

- 4. Digital Twin Technology: Simulating Perfection Before Production

- 5. Cultivating a Data-Driven Culture for Sustainable and Efficient Operations

- Soalan Lazim (Soalan Lazim)

- A Strategic Imperative for Future Growth

- Rujukan

A New Epoch for Block Manufacturing

The world of construction material production is standing at a precipice. Selama beberapa dekad, the hum of the Block making machine, the rhythmic press of the Hollow block machine, and the steady output of the Paver block machine have been the familiar heartbeats of the industry. The process was understood, tangible, and largely mechanical. Success was a function of durable machinery, skilled labor, and efficient logistics. Namun, as we navigate 2025, the ground beneath this traditional model is shifting. Manufacturers across the United States, Kanada, Korea Selatan, and Russia face a confluence of pressures that legacy systems are ill-equipped to handle.

Imagine the daily reality of a plant manager. Material costs, particularly for cement and quality aggregates, are volatile, eating into already thin margins. The demand for architectural precision has never been higher; clients now expect near-perfect uniformity in color, tekstur, and dimension across tens of thousands of units. Simultaneously, environmental regulations are tightening, scrutinizing everything from water usage to the carbon footprint of each concrete block. Add to this a persistent shortage of skilled labor willing to work in demanding industrial environments, and the challenge becomes clear. The old way of doing things, relying on experience, manual checks, and a reactive approach to maintenance, is no longer a viable path to prosperity. It has become a recipe for falling behind.

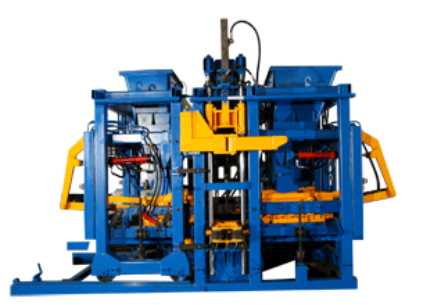

It is within this crucible of challenges that a new paradigm emerges: Smart Manufacturing in the Block Machine Industry. This is not simply about buying a newer, faster Concrete block making machine. It represents a holistic integration of digital technology into every facet of the production floor. It is about transforming a factory from a collection of isolated mechanical assets into a single, cohesive, intelligent organism that senses, thinks, and acts in real-time. This philosophy leverages a suite of powerful technologies to move beyond the limitations of human oversight and mechanical repetition.

At its core, smart manufacturing is about data. It involves capturing vast amounts of information from every stage of the block-making process—the temperature of the mix, the vibration frequency of the mold, the hydraulic pressure, the curing time—and using that data to make better decisions. The goal is to create a system that is not just automated, but autonomous; not just efficient, but optimized; not just productive, but predictive. This is the essential promise that is drawing the attention of forward-thinking leaders in the industry. The table below offers a stark comparison between the traditional approach and the smart manufacturing model, illustrating the fundamental shift in operational philosophy.

Jadual 1: Traditional vs. Smart Manufacturing in Block Production

| Ciri | Traditional Manufacturing | Smart Manufacturing in the Block Machine Industry |

|---|---|---|

| Maintenance Strategy | Reactive (fix when broken) or Preventive (scheduled) | Predictive (AI-driven forecasts of failures) |

| Kawalan Kualiti | Manual, spot-checking, subjective visual inspection | Automated, 100% inspection with computer vision, AI analysis |

| Process Control | Fixed recipes, manual adjustments based on operator experience | Dynamic, real-time adjustments via AI based on sensor data |

| Resource Management | Estimated material usage, high potential for waste | Precise tracking of materials, air, and energy; waste minimization |

| Data Utilization | Limited data collection, often logged manually on paper | Comprehensive IIoT data collection, cloud analytics, actionable insights |

| Operator Role | Manual labor, machine operation, troubleshooting | System supervision, data analysis, strategic decision-making |

| Fleksibiliti | Difficult and costly to change product lines or designs | Agile, rapid changeovers facilitated by digital twins and robotics |

This transformation is not a distant, futuristic vision. It is happening now. Companies that produce everything from simple cinder blocks to complex architectural pavers are beginning to see tangible returns on their investments in smart technologies. They are witnessing dramatic reductions in unplanned downtime, significant cuts in material waste, and a level of product quality and consistency that was previously unattainable. For manufacturers in competitive markets like North America and technologically advanced economies like South Korea, adopting the principles of smart manufacturing is rapidly becoming the definitive factor separating market leaders from followers. The journey involves a strategic application of specific, proven methodologies that directly address the core challenges of modern block production.

1. Integrating the Industrial Internet of Things (IIoT) for Predictive Supremacy

The concept of the Industrial Internet of Things, or IIoT, forms the very nervous system of smart manufacturing. Without it, the "smart" factory remains blind and numb. In the context of the block machine industry, IIoT refers to the network of interconnected sensors, actuators, and software embedded within the machinery itself, from the aggregate bins to the final cubing station. These devices continuously collect and transmit data about the health and performance of every component. This constant stream of information is the raw material from which operational intelligence is forged.

From Reactive to Predictive Maintenance

Historically, maintenance in a block production plant has followed one of two paths. The first, and most common, is reactive maintenance: a critical motor burns out, a hydraulic line bursts, or a vibrator fails, and the entire production line grinds to a halt until a technician can diagnose and fix the problem. The costs of this unplanned downtime are immense, encompassing not just the repair itself but also lost production, wasted labor, and potential contractual penalties for delayed orders. The second path is preventive maintenance, a more disciplined approach involving scheduled shutdowns to replace parts and service equipment based on fixed time intervals or usage cycles. While superior to a purely reactive model, preventive maintenance is often inefficient. Parts are frequently replaced while they still have significant operational life remaining, leading to unnecessary expense. Sebaliknya, a component might fail before its scheduled replacement, leading back to costly unplanned downtime.

Smart Manufacturing in the Block Machine Industry introduces a far more sophisticated and cost-effective model: predictive maintenance. How does a sensor on a Cement machine's mixer gearbox translate to a healthier bottom line? Imagine a small, inexpensive vibration sensor attached to the motor. In normal operation, it records a consistent vibrational signature. Over weeks of operation, walau bagaimanapun, a bearing inside the gearbox begins to wear down. This wear, imperceptible to the human ear, creates a subtle change in the vibration pattern. An IIoT platform, powered by machine learning algorithms, detects this deviation from the baseline. It recognizes the signature as an early indicator of bearing failure and automatically generates a work order, alerting the maintenance team that the component is 85% likely to fail within the next 72 hours of operation. The team can then schedule the replacement during a planned changeover, ordering the specific part in advance and avoiding any disruption to production.

This is the power of predictive supremacy. It transforms maintenance from a source of cost and disruption into a strategic, data-driven function. The return on investment is clear and multifaceted:

- Drastic Reduction in Unplanned Downtime: Studies across manufacturing sectors have shown that predictive maintenance can reduce downtime by 30-50% and breakdowns by up to 70% (Deloitte, 2022). For a high-volume Block making machine line, this translates directly into thousands of additional blocks produced per month.

- Optimized Spare Parts Inventory: Instead of stocking a vast and expensive inventory of parts "just in case," plants can move to a just-in-time model, ordering components only when the data indicates they will be needed soon.

- Increased Asset Lifespan: By addressing minor issues before they cascade into major failures, the overall operational life of expensive capital equipment like the main press, hydraulic power units, and mixers is extended.

The Sensor Ecosystem of a Smart Block Machine

To achieve this level of insight, a comprehensive sensor suite is deployed across the production line. On a modern Fully automatic block machine, one might find:

- Vibration Sensors: Attached to motors, kotak gear, and vibrator tables to detect imbalances, bearing wear, and structural stress.

- Thermal Sensors (Infrared): Monitoring electrical cabinets for overheating connections, hydraulic fluid temperatures to prevent degradation, and curing kiln temperatures for consistency.

- Pressure Sensors: Integrated into hydraulic systems to monitor for leaks, pump inefficiencies, and ensure consistent tamping pressure for uniform block density.

- Acoustic Sensors: Listening for changes in the sound of machinery that could indicate misalignment or component fatigue.

- Moisture Sensors: Placed in aggregate bins and within the concrete mixer to provide real-time data on the water content of the raw materials, allowing for precise adjustments to the mix.

- Position Sensors: Tracking the exact location and speed of conveyor belts, robotic arms, and pallet elevators to ensure synchronized operation and prevent collisions.

This data is then processed. Some initial analysis might happen at the "edge"—that is, on a small computer located directly on the machine—to allow for instantaneous adjustments. The bulk of the data, walau bagaimanapun, is typically transmitted to a cloud-based platform. Di sini, powerful analytical tools and machine learning models can analyze long-term trends, compare performance across multiple machines or plants, and refine the predictive algorithms over time. It is this continuous loop of data collection, analysis, and action that drives the relentless improvement central to the philosophy of Smart Manufacturing in the Block Machine Industry.

2. Advanced Automation and Robotics: From Raw Material to Palletization

While automation has been a part of the block machine industry for years, the "smart" factory takes it to a new level. Traditional automation often involves linear, repetitive tasks governed by simple timers and limit switches. Advanced automation, sebaliknya, is adaptive, flexible, and integrated, often incorporating robotics and machine vision to handle tasks that previously required human dexterity and judgment. This leap forward directly addresses the industry's challenges with labor costs, worker safety, and the demand for higher throughput and consistency.

The Robotic Workforce

In a state-of-the-art facility, the journey of a concrete block is a highly choreographed dance of automated systems. It begins with the automated batching plant, where the IIoT-driven system weighs the precise amounts of cement, pasir, agregat, and water for the Concrete block making machine. The mix is then transported via an automated conveyor to the main machine. Di sini, the traditional, labor-intensive process of changing molds—a task that could take hours and pose significant safety risks—is now handled by a robotic arm. Guided by the production schedule from the central MES, the robot can retrieve the correct mold from storage, unbolt the old one, and precisely position the new one in a matter of minutes. This capability alone transforms the economics of producing small, customized batches of pavers or architectural blocks.

Once the blocks are pressed and demolded, the next stage of advanced automation takes over: kawalan kualiti. Instead of a worker visually inspecting a few blocks from each pallet, a computer vision system scans every single block as it comes off the line. A high-resolution camera, coupled with specialized lighting, captures an image of each unit. An AI algorithm then analyzes this image in milliseconds, checking for:

- Ketepatan dimensi: Is the block within the specified length, width, and height tolerances?

- Surface Defects: Are there any cracks, chips, or blemishes?

- Color Consistency: For colored pavers, does the hue and distribution of pigment match the master sample?

Any block that fails to meet the stringent, pre-defined parameters is automatically rejected and diverted into a recycling stream by a small robotic arm or pneumatic pusher. This ensures that only perfect products reach the customer, virtually eliminating returns and enhancing the manufacturer's reputation for quality.

The final stage is palletizing and curing. The approved blocks are conveyed to a cubing station where a larger robotic arm, capable of handling hundreds of pounds, gently stacks them in the precise configuration required for stable transport and efficient curing. The robot can adjust the stacking pattern based on the block type and size. These "green" cubes are then transported by an automated guided vehicle (AGV) or a finger car system into the curing kiln. The system tracks each pallet, ensuring it receives the exact curing time and environmental conditions required, before moving it to the yard for storage.

Comparing Operational Models

The advantages of this highly automated approach become evident when compared to less advanced systems. The following table breaks down the key differences in a typical Paver block machine production line.

Jadual 2: Comparison of Automation Levels in Paver Production

| Operational Stage | Manual/Semi-Automatic Operation | Fully Automated (Pembuatan Pintar) Operation |

|---|---|---|

| Mold Changing | 1-2 Jam; requires multiple workers; high risk of injury. | 5-10 minit; performed by a single robot; minimal risk. |

| Quality Inspection | Manual spot-checking; inconsistent; <5% of products inspected. | 100% inspection via computer vision; objective and consistent. |

| Rejection Handling | Manual removal of defective blocks; slow; may be missed. | Automated rejection and diversion; instantaneous. |

| Palletizing (Cubing) | Manual or semi-automated stacking; physically demanding; risk of injury. | Robotic cubing; precise and fast; operates 24/7. |

| Production Speed | Limited by the speed and stamina of human operators. | Consistently high throughput, limited only by machine cycle time. |

| Keperluan buruh | Tinggi; multiple operators needed for production, QC, and material handling. | Rendah; operators transition to supervisory roles, managing the system. |

The implications for businesses in high-labor-cost markets like the US and Canada are profound. Advanced automation does not necessarily mean eliminating jobs, but rather, it redefines them. The physically demanding, repetitive, and often dangerous tasks are given to machines. Human workers are elevated to more valuable roles: system supervisors, maintenance technicians for the robotic systems, and data analysts who interpret the information generated by the smart factory. This creates a safer, more engaging work environment and helps solve the skilled labor shortage. For a business owner, it means a more reliable, predictable, and highly productive operation that can run 24/7 with minimal direct human intervention, maximizing the return on the capital investment in the Hollow block machine or other production equipment.

3. AI and Machine Learning for Process Optimization and Quality Control

If IIoT is the nervous system and robotics is the muscle of the smart factory, then Artificial Intelligence (Ai) and Machine Learning (ML) constitute its brain. These technologies provide the cognitive power to analyze the torrent of data from sensors and make intelligent, autonomous decisions that optimize the entire production process. In the block machine industry, the application of AI/ML is moving beyond theoretical concepts and is now delivering concrete, measurable results in material savings, kecekapan tenaga, dan kualiti produk.

The Self-Optimizing Concrete Mix

The quality of a concrete block is fundamentally determined by the quality of the concrete mix. Secara tradisinya, mix designs are static formulas developed in a lab. A recipe might call for a specific weight of cement, pasir, agregat, and a precise volume of water. In the real world, walau bagaimanapun, conditions are never static. The moisture content of the sand can vary depending on the weather, the ambient temperature and humidity in the factory change throughout the day, and the chemical properties of the cement can have slight variations from batch to batch. An experienced operator might make intuitive adjustments, adding a little more water here or a bit more aggregate there, but this approach is subjective and inconsistent.

This is where AI excels. A machine learning model can be trained on historical data, correlating thousands of data points—input material properties, sensor readings from the mixer (tork, suhu), and the final tested strength of the cured blocks. The model learns the complex, non-linear relationships between all these variables.

In a live production environment, the system works as follows:

- Data Ingestion: Moisture sensors in the sand and aggregate hoppers feed real-time water content data to the AI. Temperature and humidity sensors in the plant provide ambient conditions.

- AI Analysis: The AI model takes these inputs and compares them to the desired output characteristics for the block (Mis., a required compressive strength of 30 MPa). It instantly calculates the optimal adjustments needed for the current batch.

- Autonomous Action: The AI sends a command to the automated batching system, slightly reducing the amount of water added to compensate for damp sand, or minutely increasing the cement-to-aggregate ratio to counteract the effects of a cold morning.

This entire process happens in seconds, for every single batch, without any human intervention. The results are transformative.

- Simpanan bahan: The system can consistently operate closer to the minimum material requirements needed to achieve the target strength. This is particularly significant for cement, which is the most expensive and carbon-intensive component of the mix. Even a 1-2% reduction in cement usage across a year's production can lead to enormous cost savings.

- Unwavering Consistency: The AI eliminates the variability introduced by different operators on different shifts. Every block produced has a much higher likelihood of being dimensionally and structurally identical to the last.

- Adaptive Production: The system can automatically adapt to changes in raw materials. If a new shipment of aggregate has a different size distribution, the AI can learn its properties and adjust the mix design accordingly, reducing the need for extensive and costly recalibration trials.

Beyond the Visible: AI-Powered Quality Assurance

The use of AI in quality control extends far beyond the computer vision systems mentioned earlier. While those systems are excellent at detecting surface-level defects, other critical properties of a Concrete block making machine's output are invisible. The most important of these is internal structural integrity. Micro-cracks, voids, or areas of low density can compromise the strength and durability of a block, yet they are impossible to see.

Advanced Smart Manufacturing in the Block Machine Industry employs non-destructive testing methods integrated with AI. Contohnya, an ultrasonic sensor can be used to send sound waves through a block as it comes off the line. The way these waves travel through and reflect off the internal structure creates a unique signature. An AI model can be trained to recognize the signature of a perfect, high-density block versus one with internal flaws.

This allows for a level of quality assurance that was previously only possible through destructive testing (crushing a small sample of blocks in a lab). By checking the internal integrity of a much larger percentage of blocks—or even 100% of them—a manufacturer can guarantee a higher-grade product. This is a powerful selling point, especially for high-specification architectural or engineering projects where structural performance is paramount. This deep level of quality control, applied to a sophisticated Cement machine, ensures that every product leaving the factory meets not just aesthetic standards but also the most rigorous engineering requirements. Exploring the options for advanced automatic block making machines shows how these integrated quality systems are becoming a standard feature.

4. Digital Twin Technology: Simulating Perfection Before Production

Among the most advanced and powerful tools in the smart manufacturing arsenal is the digital twin. A digital twin is far more than a simple 3D model or a simulation; it is a dynamic, virtual replica of a physical asset, proses, or entire system that is continuously updated with real-world data from its physical counterpart. In the block machine industry, this means creating a living, breathing virtual model of your Block making machine, your Paver block machine line, or even your entire factory. This virtual representation allows manufacturers to test, predict, and optimize in the digital realm before committing expensive resources in the physical world.

The Virtual Proving Ground

Imagine a scenario where an architectural client requests a new, complex paver design with unique interlocking features and a multi-color blend. In a traditional setup, the process to fulfill this request would be long and costly. It would involve:

- Designing and manufacturing a new physical mold, a process that can take weeks and cost thousands of dollars.

- Running numerous test batches on the actual Paver block machine, experimenting with different mix designs, vibration settings, and curing times to achieve the desired look and strength.

- Each test batch consumes raw materials, tenaga, and valuable production time on the machine. If the initial mold design is flawed, it may need to be physically modified or remade entirely, starting the process over.

With digital twin technology, the approach is radically different. The engineer first creates a virtual model of the new paver and the corresponding mold. This virtual mold is then inserted into the digital twin of the Paver block machine. The engineer can then run hundreds of virtual production cycles in a matter of hours, not weeks. Within this virtual environment, they can:

- Simulate Material Flow: How will the concrete mix fill the intricate corners of the new mold design? Will there be air pockets?

- Optimize Machine Parameters: What is the ideal vibration frequency and duration to achieve maximum compaction without damaging the paver's delicate features? What is the optimal hydraulic pressure?

- Predict Product Properties: Based on the simulated process, the digital twin can predict the final compressive strength, ketumpatan, and even the surface texture of the virtual paver.

- Refine the Design: If the simulation reveals a flaw—for example, a weak point in the interlocking mechanism—the engineer can modify the virtual mold design and re-run the simulation instantly.

Only when the entire process has been perfected in the virtual world is the order given to manufacture the physical mold. The result is a dramatically compressed research and development cycle, a significant reduction in material waste from failed test batches, and a much higher probability that the very first physical production run will be successful. This agility allows manufacturers to be more responsive to custom orders and market trends, a key competitive advantage.

An Operator's Flight Simulator

Another powerful application of digital twins is in operator training. Moden, fully automated Hollow block machine line is a complex system. Training new operators on the live equipment can be risky; a mistake could lead to equipment damage or a safety incident. A digital twin provides a safe and realistic training environment.

New hires can interact with a virtual replica of the control panel, learning how to start and stop the line, respond to alarms, and manage production flow. The system can simulate various fault scenarios—a jammed conveyor, a sensor failure, a hydraulic pressure drop—and train the operator to follow the correct diagnostic and recovery procedures. This is analogous to how pilots train in a flight simulator. They can practice handling emergencies in a consequence-free environment, ensuring they are fully prepared before they ever touch the controls of the real aircraft—or in this case, the multi-million dollar production line. This leads to a more confident and competent workforce, reduces the risk of costly operator errors, and speeds up the onboarding process for new employees.

The implementation of Smart Manufacturing in the Block Machine Industry through digital twins represents a profound shift from a "build and test" to a "simulate and perfect" philosophy. It allows for a level of foresight and optimization that is simply impossible with physical systems alone, driving innovation while mitigating risk.

5. Cultivating a Data-Driven Culture for Sustainable and Efficient Operations

The successful implementation of Smart Manufacturing in the Block Machine Industry is not solely a technological endeavor. The most advanced sensors, robots, and AI algorithms are of little value if the organization itself does not evolve to leverage the insights they provide. Final, and perhaps most fundamental, proven way to boost ROI is to cultivate a data-driven culture. This means shifting the basis of decision-making at every level—from the plant floor to the executive suite—from intuition and historical precedent to empirical evidence and real-time data. This cultural transformation is the key to unlocking the full potential of smart technologies for long-term sustainability and profitability.

The Central Role of MES and ERP Integration

At the heart of a data-driven operation are two key software platforms: the Manufacturing Execution System (MES) and the Enterprise Resource Planning (ERP) system.

- The ERP is the central business system, managing functions like finance, sales orders, procurement, and inventory. It knows what needs to be produced and when.

- The MES is the bridge between the ERP and the plant floor. It takes the production orders from the ERP and translates them into specific instructions for the Fully automatic block machine. It also collects the real-time production data from the IIoT sensors.

In a smart factory, these two systems are seamlessly integrated. When a sales order for 50,000 hollow blocks is entered into the ERP, it automatically generates a production order in the MES. The MES then schedules the run on the appropriate Hollow block machine, ensuring the correct mold is ready and the required raw materials are available. As the blocks are produced, the MES collects data on every aspect of the run: masa kitaran, number of units produced, number of rejects, and material and energy consumption. This information is then fed back to the ERP in real-time.

This creates a transparent, end-to-end view of the entire operation. A production manager can look at a dashboard on their tablet and see the exact status of every order, the current operational efficiency of each machine, and any emerging maintenance issues. An accountant can see the precise cost of goods sold for a specific production run, based on the actual materials and energy consumed, not just an estimate.

Data for Sustainability and Cost Reduction

This granular level of data is a powerful tool for driving sustainability initiatives that also have a direct positive impact on the bottom line. Consider energy consumption. A traditional plant might only see its total electricity usage on a monthly utility bill. In a smart factory, energy meters are connected to individual machines and integrated into the MES. The system can calculate the energy consumed per block produced.

With this data, managers can ask and answer critical questions:

- Is the main press on the Concrete block making machine using more energy this month than last? This could be an early sign of a mechanical issue.

- Which of our two Paver block machine lines is more energy-efficient? Why? Can we apply the learnings from the more efficient line to the other?

- Can we shift some energy-intensive processes, like running the mixers, to off-peak hours when electricity rates are lower?

The same principle applies to material usage. By precisely tracking the consumption of cement, agregat, and water against the number of good blocks produced, the system can calculate a real-time yield. If the yield drops, it's an immediate indicator of a problem—perhaps an issue with the mix design, an increase in rejected blocks, or a leak in a water line. This allows the team to address the root cause of waste quickly, rather than discovering it weeks later during a manual inventory count.

In markets like South Korea and Canada, where environmental regulations are strict and carbon taxes are a reality, these capabilities are not just about cost savings; they are about maintaining a license to operate. Being able to demonstrate continuous improvement in energy efficiency and waste reduction with verifiable data becomes a significant competitive and regulatory advantage. Cultivating this data-driven culture, where every employee is empowered to use information to improve their part of the process, is what truly solidifies the gains from investing in the hardware of smart manufacturing. It ensures that the journey of improvement is continuous and that the ROI is not a one-time event, but a sustained, long-term benefit.

Soalan Lazim (Soalan Lazim)

What is the typical initial investment for transitioning to a smart manufacturing setup?

The initial investment can vary widely depending on the scale of the operation and the level of automation desired. A small-scale upgrade, such as adding IIoT sensors and a predictive maintenance platform to an existing Block making machine, might be in the tens of thousands of dollars. A full-scale greenfield project involving a new Fully automatic block machine with robotics, Ai, and a digital twin could represent a multi-million dollar investment. It is often approached in phases, starting with areas that promise the highest immediate ROI, like maintenance and quality control.

Do we need to hire a team of data scientists to run a smart factory?

Tidak semestinya, especially in the initial stages. Modern smart manufacturing platforms are designed with user-friendly dashboards and intuitive interfaces. The AI and machine learning models often run in the background, providing clear alerts and recommendations rather than raw data. The goal is to empower existing staff—plant managers, maintenance technicians, and quality control personnel—to make better decisions with data. While having a data-savvy person on the team is an advantage, the technology providers, such as Zenith or Lontto, often provide the necessary support and training (Zenithbrickmachine.com, 2024; Block-machine.net, 2022).

How secure is the data collected from our machines, especially if it's stored in the cloud?

Data security is a paramount concern in smart manufacturing. Reputable IIoT and cloud platform providers use robust, multi-layered security protocols, including end-to-end encryption for data in transit and at rest, secure access controls, and regular security audits. For highly sensitive operations, hybrid solutions are also possible, where critical data is processed on-premise ("at the edge") and only anonymized or summary data is sent to the cloud for long-term trend analysis.

Can smart manufacturing principles be applied to older block-making machines?

ya, secara mutlak. This is known as a "brownfield" implementation. Many older machines, while mechanically sound, lack modern controls and connectivity. They can be retrofitted with a suite of IIoT sensors, new PLC controllers, and HMI panels. This can be a very cost-effective way to gain many of the benefits of smart manufacturing, such as predictive maintenance and real-time performance monitoring, without replacing the entire production line.

What is the realistic timeframe to see a return on investment (ROI)?

The ROI timeframe depends on the specific project and the key performance indicators being targeted. For a predictive maintenance project, the ROI can often be seen within 12 kepada 18 bulan, driven by reductions in downtime and maintenance costs. For a project focused on material savings through AI-optimized mix designs, the ROI can be even faster, especially with volatile cement prices. A full-scale automation project has a longer ROI horizon, biasanya 3 kepada 5 tahun, but delivers the most significant long-term benefits in terms of labor cost reduction, keselamatan, and increased throughput.

How does smart manufacturing help in producing different types of blocks?

Smart manufacturing significantly enhances production flexibility. Digital twins allow for the rapid virtual testing of new designs for a Paver block machine or Hollow block machine. Robotic mold changing systems can reduce the changeover time between different block types from hours to minutes. An AI-powered MES can seamlessly adjust machine parameters and mix designs for different products, making it economically feasible to produce smaller, more customized batches to meet diverse market demands.

What skills should my team develop to prepare for this transition?

The focus should be on upskilling the existing workforce. Mechanical technicians will need training on the electronics and software of robotic systems. Operators will transition from manual labor to system monitoring, requiring skills in interpreting data from HMI dashboards. A basic understanding of data analysis and a problem-solving mindset become more valuable than physical strength. Investing in training programs alongside the technology is a key factor for success.

A Strategic Imperative for Future Growth

The journey towards Smart Manufacturing in the Block Machine Industry is not a mere technological upgrade; it represents a fundamental strategic reorientation. It is an answer to the complex economic, alam sekitar, and social pressures that define the industrial landscape of 2025. The five pillars discussed—IIoT for predictive maintenance, advanced robotics for automation, AI for process optimization, digital twins for virtual prototyping, and the cultivation of a data-driven culture—are not independent solutions but interconnected components of a single, cohesive strategy. bersama-sama, they enable a level of operational excellence that was unimaginable with traditional methods.

For manufacturers of all scales, from those operating a single Concrete block making machine to those managing multinational production facilities, the question is no longer if they should adopt these principles, but how and when. The transition requires careful planning, a phased approach, and a commitment to upskilling the workforce. Namun, the evidence is clear: the rewards are substantial and sustained. The ability to predict failures before they happen, to guarantee the quality of every block, to minimize waste, and to adapt swiftly to market demands are the hallmarks of a resilient and prosperous manufacturing enterprise. Embracing this evolution is the most decisive action a company can take to ensure its competitiveness, profitability, and relevance for decades to come.

Rujukan

Deloitte. (2022). Predictive maintenance. The next frontier in industrial operational excellence. Deloitte Insights.

Jentera HAWEN. (2025, Mungkin 10). How to do general maintenance for concrete block making machine? Hawenblockmachine.com. https://www.hawenblockmachine.com/automatic_concrete_brick_machine_blog/1380.html

HF Machinery. (2025, Mungkin 12). Nigerian customer visits HF machinery factory and forms strategic partnership. Cdn.hfblockmachine.com. https://cdn.hfblockmachine.com/NewsDetail/Nigerian-Customer-Visits-HF-Machinery-Factory.html

Lontto Group Co., Ltd. (2022). Sekat & brick making machine supplier. Block-machine.net.

PricewaterhouseCoopers. (2020). The Digital Twin advantage: A new paradigm for lifelong asset management. PwC.

Mesin REIT. (2025, April 29). Mesin membuat blok konkrit automatik sepenuhnya. Reitmachine.com. https://www.reitmachine.com/product-category/automatic-block-making-machine/

Sharma, R., Jabbour, C. J. C., & de Sousa Jabbour, A. B. L. (2021). Sustainable manufacturing and industry 4.0: an analysis of the existing literature and a futuristic perspective. Perancangan Pengeluaran & Control, 32(14), 1205-1221.

Siemens. (2023). Manufacturing Execution System (MES). Siemens Digital Industries Software.

World Economic Forum. (2021). The Global Lighthouse Network: Four durable shifts for a great reset in manufacturing. https://www.weforum.org/whitepapers/global-lighthouse-network-four-durable-shifts-for-a-great-reset-in-manufacturing/

Zenith Maschinenfabrik GmbH. (2024, September 20). Automatic concrete block making machine. Zenithbrickmachine.com.