Le sfide che devono affrontare i proprietari di fabbriche in mattoni

Con l'attuale natura rapida e calmata del settore delle costruzioni, Al giorno d'oggi i proprietari di fabbriche di mattoni hanno a che fare con estrema pressione per combattere gli effetti dell'aumento dei costi del lavoro, Requisiti di qualità aumentati, e la domanda di produzione ecologica e sostenibile. I metodi di produzione tradizionali in mattoni sono esattamente l'opposto, essere ad alta intensità di lavoro e talvolta molto sbilanciato in termini di produzione. Non sono in grado di soddisfare l'aumento della domanda di mattoni di cemento, blocchi cavi, e prodotti di paver in un mercato in rapido cambiamento che sta abbracciando soluzioni di costruzione efficienti e rispettose dell'ambiente.

Il passaggio all'automazione

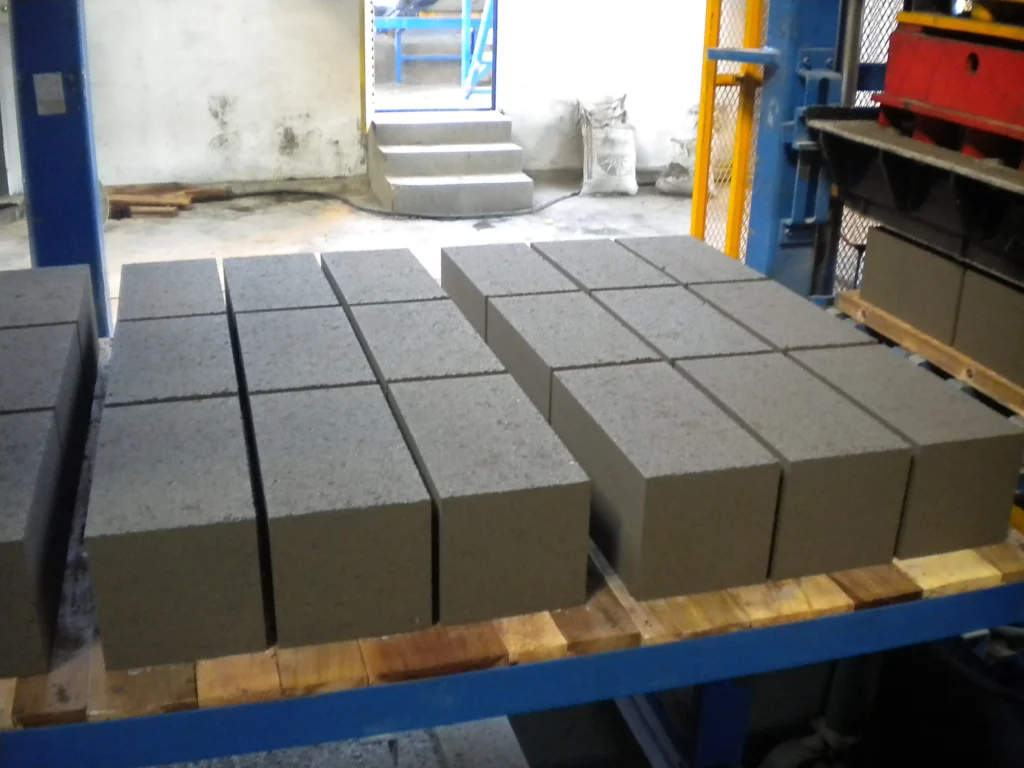

Per affrontare queste sfide, I proprietari di fabbriche si stanno spostando su REIT Macchina a blocchi completamente automatizzata. La nuova estetica dell'automazione e delle conoscenze digitali rendono le macchine a blocchi di REIT una soluzione unica-shop che è altamente efficiente e si presenta come un pacchetto completo con una garanzia di 100% Automazione di tutti i processi che iniziano con l'alimentazione di materie prime e la cenere volare allo stampaggio automatizzato ad alta precisione e all'impilamento di blocchi solidi, mattoni vuoti e pietre per pavimentazione.

Tecnologia di controllo intelligente

Il sistema di macchine a blocchi REIT è progettato con una tecnologia di controllo intelligente che garantisce la stessa qualità del prodotto, lo stesso basso tasso di errore, e allo stesso tempo, la massima efficienza di produzione. Riduzioni significative del lavoro sono fatte principalmente dalle misure prese per automatizzare non solo i costi operativi portati da una forza lavoro più piccola, ma anche promuovendo l'ambiente, salute, e sicurezza (EHS) dello stabilimento. Queste ultime macchine, anche, Cerca l'industria dei rifiuti di costruzione, in cui c'è un grande, Nobile causa di trasformare i rifiuti in prodotti per la costruzione ecologici come, tra gli altri, Eco-mattoni e cenere volante. Possiamo vedere che entrambi sono di grande aiuto all'obiettivo principale di Reto: il giro diventa una merce e la promozione della sostenibilità ambientale ecologica.

Soluzioni personalizzabili per diverse esigenze

Per i produttori di mattoni che desiderano espandere il proprio portafoglio di prodotti, Le soluzioni per macchine a blocchi personalizzabili di REIT offrono una flessibilità senza pari. Se la necessità è per blocchi di cemento standard, finitrici ad incastro, o blocchi AAC leggeri, I sistemi di REIT possono essere adattati per soddisfare una vasta gamma di requisiti di produzione in diversi settori e regioni. Con eccesso 23 Anni di innovazione continua e reputazione di marchio di fama mondiale in Block Machine Equipment, REIT garantisce che ogni macchina che offre sia supportata dall'ingegneria esperta, Servizio post-vendita reattivo, e un impegno per il successo dei clienti a lungo termine.

Conclusione

Inoltre, La macchina Block Reit è più di un semplice equipaggiamento: è una piattaforma per la crescita futura. Aggiornando la soluzione automatizzata di REIT, I proprietari di fabbrica si posizionano per l'espansione scalabile, Migliore redditività, e allineamento con le tendenze globali verso la produzione intelligente e lo sviluppo sostenibile.

Aggiorna la tua fabbrica: REIT di scelta per l'efficienza, qualità, E un domani più verde!

Voglio saperne di più? Contattaci!