Abstract

Ny firongatry ny krizy eran-tany amin'ny fako plastika dia mila vahaolana vaovao amin'ny fitantanana ny loharanon-karena. Ity tahirin-kevitra ity dia mandinika ny fizotran'ny fanovana ny fitaovana fako tsy azo averina ho an'ny ecricks, singa mahomby sy maharitra. Izy io dia manome rafitra feno amin'ny fahatakarana ny tsingerin'ny fiainan'ny famokarana biriky ekolojika, manomboka amin'ny fakana voalohany sy ny famantarana ny fako ka hatramin'ny fanasitranana farany sy ny fampiharana ireo sakana vita. Ny fanadihadiana dia mifantoka amin'ny fomba indostrialy, fanombanana ny milina, toy ny milina fanaovana sakana sy milina simenitra, ilaina mba tsy miovaova, vokatra avo lenta. Ny tohan-kevitra fototra dia ny fampitomboana ny fako amin'ny alàlan'ny fomba toy ny famokarana biriky ekolojika dia maneho fiovana fototra avy amin'ny tsipika mankany amin'ny modely ara-toekarena boribory.. Ny lahatsoratra dia mikaroka ireo fitsipika siantifika ao ambadiky ny fanomanana ara-materialy, famatrarana, ary fanasitranana, manasongadina ny maha zava-dehibe ny fanaraha-maso ny kalitao mifanaraka amin'ny fenitry ny fanorenana. Amin'ny antsipirihany ny fizotran'ny teknika, Tombontsoa ny tontolo iainana, sy ny rationale ara-toekarena, Ity asa ity dia manolotra torolàlana feno momba ny fomba hanamboarana biriky avy amin'ny fitaovana fako, Mametraka ny fampiharana ho toy ny paikady fototra ho an'ny fampandrosoana maharitra 2025.

Fitaovana fanalahidy

- Source Clean, MAINA, plastika tsy biodegradable ho an'ny tsy fivadihan'ny biriky tsara indrindra.

- Mampiasà tehim-paty matevina mba hazoto mifangaro fako matevina ao anaty tavoahangy.

- Hahatratra ny haingam-pandeha kely indrindra mba hahazoana antoka fa misy strukturally strukturally.

- Mahatakatra ny fomba hanamboarana biriky ecricks avy amin'ny fitaovana fako ho an'ny fananganana maharitra.

- Mampiasà milina indostrialy ho an'ny famokarana scaling avy amin'ny tavoahangy mankany amin'ny sakana.

- Fivarotana bitika vita amin'ny ecricks tsy lavitra ny tara-masoandro mivantana mba hisorohana ny fanimbana.

- Biriky fitsapana ho fanarahana ireo kaody fanorenana eo an-toerana alohan'ny hampiasana ireo tetikasa.

Fizahan-takelaka

- Ny tsy maintsy ilaina ny fandatsaham-panambadiana: Fahatakarana ny Revolisiona Eco-Brick

- Dingana 1: Fikarohana ara-materialy sy famaritana – Ny fototry ny Eco-Brick kalitao

- Dingana 2: Fanomanana ny akora – Ny Kanto Fanovàna

- Dingana 3: Ny fon'ny famokarana – Famoretana sy fananganana amin'ny milina fanaovana sakana

- Dingana 4: Fitsaboana sy fitsapana – Miantoka ny faharetana sy ny fanarahan-dalàna

- Dingana 5: Applications sy Integration – Fanorenana hoavy maharitra

- Fanontaniana matetika (FAQ)

- Famaranana

- References

Ny tsy maintsy ilaina ny fandatsaham-panambadiana: Fahatakarana ny Revolisiona Eco-Brick

Ny tantaran'ny fandrosoan'ny olombelona dia matetika lazaina amin'ny alalan'ny fitaovana fehezintsika: vato, varahina, VY, silisiôma. NEFA MBOLA, Ny toko misy antsika amin'izao fotoana izao dia mety ho faritana amin'ny alalan'ny fitaovana iray tsy voafehy—plastika. Ny fivondronan'ny fako plastika any an-dranomasina, endriky, ary na ny vatantsika aza dia manolotra fanamby lehibe tsy ho an'ny rafitra ara-tontolo iainana ihany fa ny fiheverantsika ny fandrosoana. Miatrika lova ara-materialy isika izay mihoatra lavitra noho ny fampiasana azy nandritra ny taonjato maro. Ny fanontaniana eo anoloantsika dia tsy resaka fanariana fotsiny fa andraikitra. Ahoana no kajy ny faharetan'ny fanjifàna? Ny foto-kevitry ny eco-brick dia mipoitra avy amin'ity olana ara-moraly sy azo ampiharina ity, manolotra lalana hamerenana sary an-tsaina ny fako tsy ho toy ny teboka farany fa ho loharanon-karena. Valiny izay mitaky endrika fifandraisana lalindalina kokoa amin'ny tontolo ara-materialy izany, izay mihodinkodina mihoatra ny fihetsika tsotra manary zavatra.

Famaritana ny Eco-Brick: Mihoatra noho ny plastika anaty tavoahangy

Amin'ny ambaratonga fototra indrindra, ny eco-brick dia tavoahangy plastika feno madio, MAINA, fako tsy azo simba amin'ny hakitroky manokana. Lasa trano fanorenana azo ampiasaina indray izy io. Ny fahatsoran'io famaritana io, na izany aza, mino ny fahasarotan'ny mety ho azy. Tsy maintsy manavaka ny endrika roa voalohany amin'ny biriky ekolojika. Ny voalohany dia biriky tavoahangy, Famoronana hetsika hetsika ara-tontolo tontolo iainana, izay fako plastika plastika ao anaty tavoahangy biby, Mamorona modely ho an'ny fananganana tsotra toy ny rindrina zaridaina na fanaka. Ny faharoa, Fomba indostrialy bebe kokoa, tafiditra amin'ny fanodinana plastika fako fako, afangaro aminy ny fatorana toa ny fasika na simenitra, ary mampiasa a milina fanaovana sakana Mba hamoronana fanamiana, barazy avo lenta.

Raha ny biriky tavoahangy tavoahangy dia fitaovana mahery vaika ho an'ny fanabeazana fitantanana fako, Ny ecrick indostrialy dia vahaolana mikendry ny fanovana rafitra eo amin'ny indostrian'ny fananganana. Tsy vazivazy fotsiny ireo fako; Izy ireo dia vokatra injeniera. Ny dingana dia mitaky fahatakarana siansa siansa momba ny siansa ara-nofo - ny fomba samy hafa ny fihetsiky ny polymers, Ahoana no ifandraisan'ny binders miaraka amin'ny ozona plastika, ary ny fomba hanatanterahana ny vokatra farany amin'ny adin-tsaina isan-karazany. Mianatra ny fomba hanamboarana biriky avy amin'ny fitaovana fako ao amin'ny kontitra indostrialy dia midika miaraka amin'ny simika, Fizìka, ary injeniera hanova andraikitra amin'ny fananana maharitra.

Ny fanavotana ara-tontolo iainana sy toekarena ho an'ny biriky ecricks

Ny fanamarinana amin'ny fananganana teknolojia ecrick dia roa heny, miorim-paka amin'ny fitantanana ny tontolo iainana sy ny pragmatism ara-toekarena. Toetoetra, Mazava ny tombontsoa azo. Isaky ny fako plastika rehetra izay niova fo ho ecricks dia tonony tsy voaroaka, landfilled, na tsofina ao amin'ny tontolo iainana an-dranomasina (Azevedo et al., 2022). Ny fizotran'ny fizahana dia mahomby amin'ny fomba mahomby amin'ny karbonina ao anaty plastika, hisorohana ny famotsorana azy ao anaty habakabaka. koa, Amin'ny fanoloana ny tanimanga nentim-paharazana na ny biriky mivaingana, Ny famokarana biriky Eco-Brick dia mety hampihena ny dian-tongotry ny karbonika amin'ny sehatry ny fananganana. Ny biriky tanim-boninkazo voaroaka dia mazoto miasa mafy, mitaky solika be dia be ho an'ny kilao, Raha ny famokarana simenitra dia loharano mitarika ny fivoaran'ny CO2 CO2 maneran-tany.

ara-toekarena, Ny modely dia manolotra tolo-kevitra momba ny lanjany. Izy io dia manova fitaovana miaraka amin'ny fako tsy misy dikany izay mandoa vola ny kaominina. Ho an'ny fokonolona, Izy io dia afaka mamorona asa eo an-toerana amin'ny famoriam-bola fako, fanasokajiana, sy ny fanodinana. Ho an'ny orinasa fananganana, Manome fitaovana fanorenana mety ho ambany izy io, mampihena ny fianteherana amin'ny harena virjiny izay matetika ny vidiny dia matetika miforitra. Ny fampiasana a Masinina paver block Ny noforonina manokana ho an'ireo fitaovana ireo dia afaka mamorona tsena vaovao ho an'ny tetik'asa fotodrafitrasa maharitra, Avy amin'ny làlam-bahoaka mankany amin'ny ivon'ny fiaraha-monina. Ny lojika ara-toekarena dia ny toekarena boribory: Tsy fako ny fako raha tsy lany andro. Amin'ny famolavolana rafitra iray izay misambotra ny lanjany ara-nofo, Mamorona modely ara-toekarena sy mahomby kokoa isika.

Fiovan'ny filozofia: Avy amin'ny fako lalandava amin'ny loharanon-karena boribory

Ny tena mahatakatra ny maha-zava-dehibe ny ecrick, Ny iray dia tsy maintsy mankasitraka ny filozofia filozofia izay asehony. Ho an'ny ankamaroan'ny vanim-potoana indostrialy, Ny maodely ara-toekarena dia misy tsipika: Raiso, ataovy, Ario. Izahay dia maka loharanon-karena, Vokatra vokatra, ary esory izy ireo rehefa tsy ilaina intsony. Ity modely ity dia mihevitra ny loharanom-pahalalana tsy manam-petra sy ny fahafahan'ny tsy manam-petra ho an'ny planeta mba handroaka fako. Ny taonjato voalohany tamin'ny roapolo amby roapolo dia nanohitra ireo fiheverana ireo. Ny toekarena boribory, Mifanohitra amin'izany, dia famerenana sy famerenana indray amin'ny famolavolana. Tanjona ny hitazomana ny vokatra, singa, ary ny fitaovana amin'ny fampiasana sy sandany ambony indrindra amin'ny fotoana rehetra.

Ny fanao amin'ny fianarana ny fomba fanamboarana biriky ekolojika amin'ny akora fako dia fanehoana an'io filozofia boribory io.. Hetsika fitsabahana izay manakorontana ny lalana mizotra mankany amin'ny fanariam-pako. Manery ny fanombanana indray ny zavatra arianay izany, mangataka antsika tsy hijery fako fa fahafahana. Manohitra ny fahazarantsika ara-kolotsaina amin'ny fanariana izany, mitaky fifandraisana misaina kokoa amin'ny fananantsika ara-nofo. Amin'izany heviny izany, Ny biriky ekolojika dia mihoatra noho ny trano fanorenana; fitaovana ara-pedagojika io. Mampianatra lesona momba ny fahatsiarovan-tena ara-materialy izany. Ny dingana famoronana iray, na tanana na milina, mampirisika ny fahatakarana lalina ny hamaroan'ny fako sy ny faharetan'ny fako avoakantsika. Izy io dia fisehoana azo tsapain-tanana amin'ny etika vaovao amin'ny fanjifana, iray miorina amin'ny andraikitra sy fahaizana.

Dingana 1: Fikarohana ara-materialy sy famaritana – Ny fototry ny Eco-Brick kalitao

Ny fahamarinan'ny firafitra rehetra dia manomboka amin'ny kalitaon'ny singa fototry ny fanorenany. Ao amin'ny tontolon'ny biriky ecricks, Ny "Foundation" ny fako ihany ve. Ny vokatra farany dia mety ho matanjaka ihany, maharitra, ary azo antoka fa toy ny fidirana ampiasaina hamoronana azy. Ny fomba haketahana iray amin'ny fanangonana ara-pitaovana dia tsy azo ihodivirana amin'ny biriky substandard, iray izay mety tsy mahomby, Leach manimba simika, na manimba ny prematurely. Ary noho izany, Ny fomba fiasa ara-tsiansa sy siansa momba ny famotehana sy ny toetra dia tsy dingana mialoha ny safidy fa ny orinasam-pifandraisana mahomby amin'ny orinasa Eco-Brick Production. Mitaky ny sain'ny simia sy ny injeniera mifehy ny kalitao, Misafidy sy famakafakana am-pitandremana ireo fitaovana fambolena mba hahazoana antoka fa mifanaraka amin'ny fepetra takiana amin'ny vokatra vita amin'ny fananganana. Ny dia ny fomba hanamboarana biriky avy amin'ny fitaovana fako amin'ny fako dia manomboka eto, miaraka amin'ny maso mahay manavaka izay safidintsika mba hamerenana azy.

Famantarana ny renirano fako mety: Plastika, Aggregates, sy ny bindera

Ny teny hoe "fako" tsotra mora foana. Raha ny tena izy, Ny renirano fako mivaingana dia fifangaroana heterogeneus fitaovana tsy tambo isaina, tsirairay avy amin'ny fananana simika sy ara-batana tsy manam-paharoa. Tsy ny fako rehetra dia mety amin'ny famokarana biriky Eco-Brick. Ny kendrena voalohany dia plastika post-mpanjifa, indrindra ireo izay sarotra amin'ny famerenam-bokatra amin'ny fomba mahazatra. Matetika ireo dia misy sarimihetsika mora azo (Ldpe), fonosana maro karazana, ary ny plastika masiaka sasany (p, Sal).

Ny plastika mety ho an'ny famokarana ecrick dia madio, MAINA, ary tsy biodegradable. Fandotoana organika, toy ny sakafo sisa tavela, Mety hitarika amin'ny fitomboan'ny mikraoba ao anaty biriky, mamokatra entona izay mety hanimba ny fahamarinany ara-drafitra ary miteraka loza voajanahary mety hitranga. Fahavalo lehibe koa ny hamandoana, satria mety hanelingelina ny fizotran'ny famatorana ary hitarika amin'ny tsindry etona anatiny mandritra ny famokarana mifototra amin'ny hafanana.

Ankoatra ny plastika, Ny famokarana biriky indostrialy dia misy singa hafa.

- Aggregates: Anisan'izany ny fitaovana nentim-paharazana toy ny fasika fa ny fako hafa naverina tamin'ny laoniny toy ny vera voatoto, fanamboarana fanorenana, na ny fatana fatana aza. Ny aggregates dia manome hery betsaka sy compressive.

- Binders: Ny binder dia ny lakaoly izay mitazona ireo singa. Ny simenitra Portland dia safidy mahazatra, fa ny mpikaroka dia mikaroka fomba hafa maharitra kokoa, toy ny geopolymers azo avy amin'ny vokatra indostrialy toy ny lavenona (PHE, 2017). The choice of binder is a determining factor in the brick's final properties and environmental footprint.

| Karazana fitaovana fako | Code polymer | Loharanom-baovao iraisana & OHATRA | Ny mety ho an'ny biriky indostrialy | Fandinihana fototra |

|---|---|---|---|---|

| Polyethylene terephthate | 1 (Pet) | Soda / tavoahangy rano, siny sakafo | mampitony | Mangatsiaka be, mafy. Matetika manana sanda avo lenta, ka mety ho tsy misy na inona na inona ho an'ny biriky ecricks. |

| Polyethylene avo lenta | 2 (HDPE) | Jugs ronono, tavoahangy shampoo, fantsona | Avo | Tanjaka tsara sy fanoherana simika. Milentika tsara ary mampiditra amin'ny fomba mahomby amin'ny binders. |

| Polyvinyl klorida | 3 (PVC) | fantsona, Frame amin'ny varavarankely, Ny fonosana sasany | IVA | Mamoaka entona HCL mampidi-doza rehefa mafana. Amin'ny ankapobeny dia misoroka amin'ny fomba fampiantranoana thermal. |

| Polyethylene ambany | 4 (Ldpe) | Kitapo plastika, Sarimihetsika, lids | Avo | Mora sy henjana. Mety ho fanamby amin'ny fihenam-bolo nefa miasa ho toy ny famenoana tsara sy ny binder rehefa miempo. |

| Polypropylene | 5 (p) | fitoeran, Fiara fiara, karipetra | Avo | Fanoherana ny havizanana tsara sy ny teboka miempo avo. Fitaovana fampidirana be sy tsara indrindra. |

| Polystyrene | 6 (PS / EPS) | Kaopy azo ampiasaina, Foam Packaging | mampitony | Marefo toy ny mafy orina (Sal), voluminous toy ny foam (EPS). Afaka mamoaka styrene rehefa mafana. Mitaky fitandremana amim-pitandremana. |

| Plastika hafa / mifangaro | 7 | Fonosana maro karazana, composites | Variable | Ny tena "tsy azo tanterahina" stream. Mitaky fandaharam-potoana saro-pantarina na dingana matanjaka izay mahazaka polymers mifangaro. |

Ny siansa siansa: Manual vs. Systems automatique

Vantany vao fantatra ny ranonorana mety hitranga, Ny asa manakiana ny fandalovana dia manomboka. Ny tanjona dia ny hampisaraka ny plastika ilaina amin'ny klaminant sy ny fako hafa. Ny fomba fiasa dia afaka miovaova avy amin'ny boky iray manontolo mba ho automatique tanteraka, Miankina amin'ny haben'ny fandidiana sy ny fampiasam-bola azo ampiasaina.

Ny fandaharam-pampianarana manual no endrika fototra indrindra. Ireo mpiasa eo amin'ny tsipika fanasokajiana dia mamantatra sy misaraka ara-batana ny fitaovana. Raha miasa mafy, mety hahomby tokoa izany, indrindra amin'ny tetikasa mifototra amin'ny fiaraha-monina. Ny mpanala olombelona dia azo ampiofanina hamantatra ireo karazana fonosana manokana ary hanao fitsarana mivaingana momba ny haavon'ny loto izay sarotra ho an'ny milina.. na izany aza, miadana izany, miteraka loza mety hitranga amin'ny fahasalamana ho an'ny mpiasa, ary tsy mora scalable ho an'ny trano indostrialy lehibe.

Ny rafitra fanasokajiana mandeha ho azy dia maneho ny manara-penitra. Ireo fitaovana ireo dia mampiasa andianà teknolojia avo lenta mba hanavahana ny fako.

- Optical Sorters: Infrarouge akaiky (NIR) Ny spectroscopy dia teknolojia manan-danja. Rehefa mandalo amin'ny fehikibo conveyor haingam-pandeha ny fitaovana, Ny sensor dia manazava azy ireo amin'ny hazavana NIR. Ny polymère samihafa dia maneho ny hazavana amin'ny endrika spectral tokana, mamela ny solosaina hamantatra ny fitaovana ao anatin'ny milisegondra. Ny rivotra voatsindry tsara avy eo dia manosika ilay zavatra fantatra ho ao amin'ny dabam-pako. Ity teknôlôjia ity dia mamela ny fisarahana amin'ny fahadiovana ambony amin'ny plastika toy ny PET, HDPE, ary PP.

- Separator amin'ny hakitroky: Mampiasa rano na ranon-javatra hafa amin'ny hakitroky manokana ny tanky mitsingevana hanasarahana fitaovana. Ohatra, polyolefins toy ny PE sy PP dia hitsingevana anaty rano, raha hilentika ny plastika matevina kokoa toa ny PET sy PVC.

- Mpisaraka amin'izao fotoana izao andriamby sy Eddy: Ireo dia ampiasaina hanesorana ferrous (VY, vy) ary tsy ferrous (VIRATY) metaly avy amin'ny fako, miaro ny fitaovana ambany toy ny shredder amin'ny fahasimbana.

Ho an'ny hetsika indostrialy mifantoka amin'ny fomba fanamboarana biriky ekolojika amin'ny akora fako, Ny fomba hybrid dia matetika no tsara indrindra. Boky voalohany "pre-sort" manala loto lehibe sy zavatra manahirana alohan'ny hidiran'ny riaka amin'ny rafitra mandeha ho azy mba hisarahana tsara..

Fanaraha-maso kalitao: Fanombanana ny fandotoana sy ny fananana ara-materialy

Ny fanasokajiana no tsipika fiarovana voalohany, fa tsy mety diso. Fanaraha-maso kalitao henjana (QC) Ny protocol dia tena ilaina mba hanamarinana ny fahadiovan'ny fitaovana voafantina alohan'ny hidirany amin'ny dingana famokarana. Ny fanamarinana QC dia tokony hatao isaky ny ampahany amin'ny akora.

Ny tena zava-dehibe dia ny fandotoana. Ny santionany avy amin'ny andiany dia tokony hojerena amin'ny maso ho an'ny fitaovana tsy lasibatra toy ny taratasy, zavatra organika, metaly, na fitaratra. Fitsapana "wash" afaka manombana ny haavon'ny loto sy ny loto. Ny lanjan'ny plastika fantatra dia sasana, maina, ary nolanjaina indray; ny fahasamihafan'ny lanjany dia manondro ny isan-jaton'ny loto. Ny ankamaroan'ny dingana indostrialy dia hanana haavon'ny fandotoana ambony indrindra azo ekena, matetika ambany 2%.

Ankoatra ny fahadiovana, Ny fanombanana ny toetra ara-materialy ny plastika dia tena sarobidy. Fanondroana Melt Flow (MFI) fitsapana, ohatra, afaka mandrefy ny viscosity ny plastika rehefa levona. Ny MFI tsy miova dia zava-dehibe ho an'ny dingana misy ny extrusion na ny famolahana tsindrona, satria miantoka ny fikorianan'ny fitaovana amin'ny milina. Na dia mandroso loatra aza ho an'ny asa madinika, ho an'ny orinasa mamokatra blocs avo lenta miaraka amin'ny sophisticated Masinina fanaovana bloc beton, such data is invaluable for process control and ensuring the final product's consistency. Ity dia fifehezana, Ny fomba fiasa mifototra amin'ny angon-drakitra dia mampiakatra ny fomba fanao avy amin'ny fanariana fako tsotra ho amin'ny tena injeniera fitaovana.

Dingana 2: Fanomanana ny akora – Ny Kanto Fanovàna

Miaraka amin'ny famatsiana madio, Nalahatra, ary plastika fako voafehy tsara, manomboka ny dingana manaraka. Dingana iray amin'ny fiovan'ny fizika ary indraindray ny zavatra simika, izay ny akora dia voaomana tsara ho amin'ny fiainany vaovao ho toy ny singa fanorenana. This preparation phase is analogous to a chef's mise en place—the careful chopping, Nandrefy, ary fampifangaroana ny akora alohan'ny hanombohan'ny tena fandrahoan-tsakafo. Dingana tsirairay—fanadiovana, fanapotehana, ary ny fampifangaroana—dia niniana natao mba hanamafisana ny fitaovana ho an'ny fizotry ny famoretana sy ny fananganana manaraka. Ny fahombiazan'ny eco-biriky farany dia miankina amin'ny fahamendrehana natao teto. Ny tsy fijerena ny antsipiriany amin'ity dingana ity dia mety hiteraka olana misesisesy any aoriana, manomboka amin'ny tsy fahombiazan'ny milina ka hatramin'ny vokatra farany tsy ampy ara-drafitra. Ny fifehezana ny fomba fanamboarana biriky ekolojika amin'ny akora fako dia, amin'ny ampahany betsaka, mahafehy io kanto fanomanana io.

Fanadiovana sy fanadiovana: Fiantohana ny fiarovana sy ny fahamendrehana ara-drafitra

Na dia aorian'ny fanasokajiana aza, ny fako plastika voaangona dia mety hihazona ny fahalotoan'ny ety ambonin'ny tany—loto, VOVOKA, lakaoly, ary ny sisa organika. Ny fanesorana ireo loto ireo dia tsy resaka estetika fotsiny; fototra ho an'ny fiarovana sy ny fanatanterahana izany. Amin'ny lafiny fiarovana, Ny fanadiovana ny plastika dia manala ireo otrikaretina mety hitranga, miaro ny mpiasa ary miantoka ny fahadiovan'ny vokatra farany ampiasaina amin'ny fanorenana. Avy amin'ny fomba fijery fampisehoana, Ny plastika madio dia ilaina amin'ny famatorana tsara. Ny adhesives sy ny sarimihetsika organika dia mety ho toy ny sakana, fisorohana ny binder (na plastika nitsonika mihitsy na additives toy ny simenitra) avy amin'ny fananganana fatorana mafy amin'ny fitambarana plastika. Ity interface malemy ity dia mety ho lasa teboka tsy fahombiazana amin'ny biriky vita.

Ny dingan'ny fanadiovana mazàna dia misy tsipika fanasan-dahatra maromaro.

- Fanasana mialoha: Arotsaka ao anaty rano aloha ilay plastika mba hanesorana ny loto sy ny etikety.

- Fanasana mafana: Ny fitaovana dia miditra amin'ny fandroana rano mafana, matetika miaraka amin'ny soda caustic (ny sodium hydroxide) vahaolana. Ity fanasan-damba mahery vaika ity dia manafosafo ny menaka sy ny tavy ary manalefaka ny adhesive sy ny sisa tavela..

- Fanasana: Manaraka dingana maro ny fanasan-damba mba hanesorana ireo savony sy loto.

- namaoka: Farany, ny plastika madio dia tsy maintsy ho maina tsara. Dingana lehibe izany. Ny hamandoana sisa tavela dia mety hivadika ho etona mandritra ny fanerena mifototra amin'ny hafanana, mamorona banga sy tsindry anatiny izay mampalemy ny biriky. Ny fomba fanamainana indostrialy dia misy fanamainana centrifugal, izay manodina ny rano, arahin'ny fanamainana mafana izay mampiasa rivotra mafana mba hanesorana ny hamandoana farany.

| Fomba famokarana | Description | Fidirana fako voalohany | Karazana binder | Intensity fitaovana | Vokatra farany |

|---|---|---|---|---|---|

| Bricking tavoahangy | Famenoana tanana madio, fako maina ao anaty tavoahangy PET amin'ny hakitroky manokana. | Ny fako rehetra tsy mety simba izay azo tapahina/foritra mba hifanaraka. | tsy misy (fametahana mekanika). | Ambany be (tapa-kazo ho an'ny entana). | Module fanorenana azo ampiasaina ho an'ny fampiharana tsy ara-drafitra. |

| Compression Molding | Afanaina ny plastika nopotehina ary atsipazo ao anaty lasitra. Ny plastika mihitsy no miasa toy ny binder. | Thermoplastics (HDPE, Ldpe, p). | Mamatotra tena (plastika mitsonika). | antonony hatramin'ny avo (shredder, lafaoro/fanafana, milina hydraulic). | mikitroka, vato mafy ho an'ny paving, MANDAN'I. |

| Extrusion | Ny plastika dia miempo ary terena amin'ny alalan'ny die mba hamoronana profil mitohy, izay tapahina amin'ny halavany avy eo. | Thermoplastics (HDPE, Ldpe, p). | Mamatotra tena (plastika mitsonika). | Avo (shredder, extruder, tsipika fampangatsiahana, mpanapaka). | « Kitapo plastika," Lahatsoratra, rairainy, hazo fisaka. |

| Plastic-Fasika/Cement Composite | Ny plastika nopotehina dia afangaro amin'ny fasika sy/na simenitra ary rano kely, dia tsindriana. | Ny karazana plastika rehetra (anisan'izany ny thermosets), fasika, simenitra. | Simenitra / Pozzolanic binder. | Avo (shredder, mixeur, Masinina sakana hollow). | Boky betonina misy insulation tsara. |

Fametahana sy Granulating: Fahatakarana ny haben'ny singa tsara indrindra

Rehefa madio sy maina, ny plastika—izay mety ho endrika tavoahangy, fitoeran, na sarimihetsika-tsy maintsy ahena ho fanamiana, habe potika azo fehezina. Izany dia vita amin'ny alàlan'ny shredder indostrialy sy granulators. Ny safidy amin'ny milina sy ny haben'ny sombin-javatra farany dia tsy kisendrasendra; they are carefully chosen variables that have a profound impact on the subsequent processing and the final brick's characteristics.

- Shredders: Ireo dia avo-torque, milina ambany hafainganam-pandeha natao ho an'ny fampihenana ny habeny voalohany. Afaka maka lehibe izy ireo, zavatra goavana toy ny amponga plastika na amboara misy sarimihetsika ary vakio ho kely kokoa, sombin-javatra marokoroko, matetika santimetatra vitsivitsy ny habeny.

- Granulators: Ireo dia milina haingam-pandeha izay maka ny vokatra avy amin'ny shredder ary mampihena izany ho kely, granules mitovy na flakes, matetika mandalo ny fitaovana amin`ny alalan`ny efijery amin`ny habe manokana lavaka (E.g., 10MG).

Ny fitsinjarana ny haben'ny sombin-javatra tsara indrindra dia mason-tsivana fototra.

- Lehibe loatra: Ny poti-javatra lehibe dia afaka mamorona banga amin'ny biriky farany, mitarika ho amin'ny toerana malemy. Miempo na mifangaro tsy dia mahomby koa izy ireo.

- Kely loatra: Ny famoronana vovony tena tsara dia mitaky angovo be dia be ary afaka miteraka vovoka, izay mety ho loza mipoaka. na izany aza, ny fifangaroan'ny haben'ny poti dia matetika tiana. Toy ny amin'ny beton, izay misy fitambarana lehibe (vatokely) ary mitambatra tsara (fasika), Ny fizarana plastika misy naoty tsara dia mamela ny famonosana matevina kokoa. Ny potikely kely kokoa dia mameno ny banga eo anelanelan'ny lehibe kokoa, miteraka matanjaka kokoa, biriky kely kokoa. Ny dingana amin'ny fananganana biriky eco-biriky avy amin'ny akora fako dia mitaky antsipirihan'izany, mifindra mihoatra ny fanariana tsotra mankany amin'ny injeniera ara-materialy.

Fampifangaroana sy fampifangaroana: Ny anjara asan'ny mpamadika sy ny additives

Ho an'ny biriky ekolojika izay tsy vita amin'ny plastika mitsonika, ny dingana fampifangaroana no ivondronan'ny recipe. Ny granules plastika nopotehina dia mitambatra amin'ny binder voafidy sy ny additives hafa ao anaty mixer indostrialy lehibe.. Ny tanjona dia ny hamorona fifangaroana homogeneous tanteraka, miantoka fa ny ampahany tsirairay amin'ny biriky farany dia mitovy ny fitambarany.

Raha misy binder simenitra ampiasaina, ny granules plastika, fasika (na fitambarana hafa), simenitra, ary atambatra ny habetsahan'ny rano. Ny tahan'ny plastika amin'ny fasika amin'ny simenitra dia ampahany manan-danja amin'ny "design mix" and will determine the brick's compressive strength, lanja, ary ny toetra mahamay (Ny masoko & Adesina, 2020). A specialized milina simenitra na ozinina fanangonam-bokatra vita amin'ny simenitra dia azo ampiasaina mba hahazoana antoka fa ireo akora ireo dia refesina sy mifangaro amin'ny mari-pamantarana avo lenta, izay tena ilaina amin'ny famokarana tsy miovaova, blocs avo lenta.

Amin'ny formulations mandroso sasany, azo ampidirina ny additives hafa:

- loko: Mba hanomezana loko manokana ny biriky.

- UV Stabilizers: Mba hiarovana ny plastika amin'ny fahasimbana noho ny fiposahan'ny masoandro, indrindra raha ny biriky dia ampiasaina amin'ny ety ivelany.

- Flame Retardants: Mba hanatsarana ny kalitaon'ny fiarovana ny afo amin'ny vokatra farany, fiheverana lehibe ho an'ny fitaovana fanorenana.

Tsy maintsy fehezina tsara ny fampifangaroana azy. Ny fampifangaroana tsy ampy dia miteraka clumping sy toerana malemy, raha be loatra ny fangaro dia mety ho fandaniam-bola na, amin'ny toe-javatra sasany, afaka manomboka manimba ny fitaovana. Ny vokatr'ity dingana ity dia fitaovana vita amin'ny composite voarindra tsara, vonona ny homena ny endriny farany.

Dingana 3: Ny fon'ny famokarana – Famoretana sy fananganana amin'ny milina fanaovana sakana

Izao no fotoana famoronana, aiza ny voaomana, amorphous fifangaroan'ny fitaovana dia ovaina ho mafy, endrika voafaritra. Ny dingana famoretana sy fananganana no ivon'ny tsipika famokarana biriky eco-biriky indostrialy. Eto ny angovo mety ho voatahiry ao amin'ny akora malalaka dia ovaina ho tsy mitongilana ara-drafitra ny biriky.. Ny safidy ny milina, ny mason'ny dingana, and the design of the molds all converge to define the final product's quality, Bika Aman 'endrika, sy ny fampisehoana. Ity dingana ity dia fanehoana mahery vaika ny fomba azo ampiasaina amin'ny tanjona ara-tontolo iainana ny teknolojia indostrialy. Ny feon'ny milina fanontam-pirinty hydraulika na ny tsingerin'ny gadona milina iray dia lasa feon'ny fako ateraka indray ho singa fanorenana sarobidy.. Tsy afa-misaraka amin'ny fahatakarana ny asan'ireo milina matanjaka ireo ny fahatakarana ny fomba fanamboarana biriky ekolojika amin'ny akora fako amin'ny ambaratonga..

Mifidy ny fitaovana mety: Avy amin'ny milina fanerena amin'ny tanana ka hatramin'ny milina fanakanana mandeha ho azy tanteraka

Ny teknôlôjia ampiasaina amin'ny famatrarana dia mety miovaova be amin'ny haingo, MIRARY, ary output.

- Manindry manual: Amin'ny faran'ny faran'ny spektrum dia misy visy na hydraulika ampiasaina amin'ny tanana. Vidiny mora ireny ary tsy mila herinaratra, mahatonga azy ireo mety ho an'ny madinika, asa ivelan'ny tambajotra. na izany aza, voafetra sy tsy mifanaraka ny tsindry azon'izy ireo ampiharina, mitarika amin'ny fiovaovan'ny haavon'ny biriky sy ny tanjaky. Tena ambany koa ny vokatra azony.

- Presses hydraulic: Ireo no workhorses ho an'ny asa antonony maro, indrindra fa ireo mampiasa compression molding izay afanaina plastika. Ny rafitra hydraulic dia afaka miteraka lehibe, tsindry azo fehezina, miantoka fa ny akora dia miraikitra mafy ao anatin'ny lasitra.

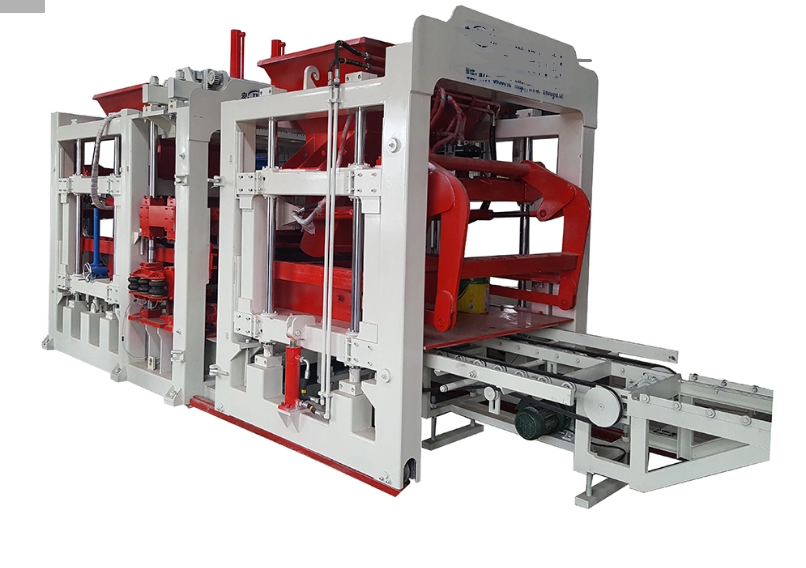

- Milina fanaovana sakana: Ho an'ny famokarana biriky mitambatra avo lenta (plastika-simenitra-fasika), milina fanaovana sakana manokana no safidy mahomby indrindra. Ireo milina ireo dia fahita matetika amin'ny famokarana bozaka vita amin'ny simenitra nentim-paharazana saingy mifanaraka tsara amin'ny famokarana biriky ekolojika. Matetika izy ireo dia miasa amin'ny fampifangaroana ny fametahana fanerena avo lenta miaraka amin'ny vibration mahery vaika. Ny vibration dia manampy ireo poti-javatra hipetraka ao anatin'ny fandaharana faran'izay mafy indrindra, mampihena ny banga ary miantoka ny fizarazarana ny binder.

- Masinina fanakanana mandeha ho azy tanteraka: Izany dia maneho ny faratampon'ny teknolojia famokarana. Amin'ny rafitra mandeha ho azy tanteraka, ny dingana manontolo — manomboka amin'ny fampidirana ireo akora mifangaro ao anaty lasitra, ho manindry sy mihovitrovitra, ny de-volavola ny biriky vita amin'ny pallet—dia fehezin'ny ordinatera (PLC). Manamaivana ny asa izany, maximize ny vokatra (matetika mamokatra sakana an'arivony isan'ora), ary miantoka ny tsy fitoviana tsy manam-paharoa avy amin'ny biriky iray mankany amin'ny manaraka. Ho an'ny orinasa mitady ho lasa mpamatsy lehibe amin'ny eco-bricks, ny fampiasam-bola amin'ity ambaratongan'ny automatique ity dia ilaina stratejika.

Ny Mechanics of Compression: tsindry, hafanana, sy Dwell Time

Na inona na inona milina ampiasaina, masontsivana manan-danja telo no mifehy ny dingan'ny famoretana: tsindry, hafanana, ary fotoana hipetrahana.

- tsindry: The amount of force applied per unit area is perhaps the single most important factor in determining the brick's density and compressive strength. Ny fanerena ambony kokoa dia manery ireo potikely hifanakaiky, mampihena ny porosity ary mamorona fatorana matanjaka kokoa eo amin'izy ireo. Ny fanerena ilaina dia miovaova arakaraka ny fangaro akora, fa matetika ao anatin'ny isan-karazany 10 ny 30 megapascals (MPa).

- hafanana: Ho an'ny dingana mifandraika amin'ny fandoroana plastika (fanodinkodinana lasitra), mari-pana dia fari-pitsipika manan-danja. Ny fitaovana dia tsy maintsy hafanaina eo ambonin'ny teboka mitsonika mba hikoriana sy hitambatra, fa tsy dia avo loatra ka manomboka miharatsy ny hafanana, izay afaka mamoaka setroka misy poizina sy manalefaka ny fitaovana. Ny karazana plastika tsirairay dia manana varavarankely fanodinana manokana momba ny mari-pana. Ho an'ny biriky simenitra mifototra amin'ny tontolo iainana, ny dingana dia atao amin'ny mari-pana manodidina, noho izany dia tsy dia mampanahy loatra ity paramètre ity.

- Dwell Time: Izany no halavan'ny fotoana fanerena (ary hafanana, raha azo ampiharina) dia tazomina. Ilaina ny fotoana ipetrahana ampy mba hahafahan’ilay akora hiraikitra tanteraka, mba handosirana rivotra, ary ho an'ny poti-javatra mba hamorona fatorana mafy orina. Raha avoaka haingana loatra ny tsindry, ny biriky dia mety "miverina" na manitatra, ka mahatonga ny hakitroky ambany sy ny rafitra malemy kokoa.

Ezaka ara-tsiansa ny fanatsarana ireo fari-piainana telo ireo, matetika mitaky fanandramana be dia be mba hahitana ny fomba fanamboarana tonga lafatra ho an'ny fangaro ara-nofo nomena sy ny fananana biriky irina. Eto ny fahalalana ny fomba fanamboarana biriky ekolojika avy amin'ny akora fako dia miova avy amin'ny fitsipika ankapobeny mankany amin'ny manokana, fahalalana ny fizotran'ny proprietary.

Mold Design: Mamolavola ny hoavin'ny fanorenana

Ny lasitra no manome ny birikiny ny endriny farany sy ny refy. Raha ny sakana mahitsizoro tsotra no endrika mahazatra indrindra, Ny famolavolana bobongolo dia manome fahafahana lehibe ho an'ny fanavaozana. Ny lasitra dia azo natao mba hamoronana biriky mifamatotra, izay mety hampihena na hanafoana mihitsy aza ny filana laona, manafaingana ny fanorenana sy mamorona rindrina mafy kokoa. Afaka mamorona sakana poakaty izy ireo, izay maivana kokoa, manome insulation mafana sy acoustic tsara kokoa, ary mila fitaovana kely kokoa isaky ny sakana. ny Masinina sakana hollow dia natao manokana miaraka amin'ny lasitra izay manana cores anatiny hamokarana ireo banga ireo.

Ny lasitra ho an'ny famokarana indostrialy dia tokony ho mafy orina. Matetika izy ireo dia vita amin'ny vy mafy mba hanohitra ny fanerena goavana sy ny hetsika abrasive ny fitaovana mandritra ny tsingerina an'arivony.. Ny faritra anatiny dia matetika voapoizina amin'ny fitaratra vita amin'ny fitaratra mba hahazoana antoka fa malama amin'ny biriky ary hanamora ny famolahana mora.. Ny famolavolana dia tsy maintsy mitatitra kely ihany koa (drafitra zoro) mba hamela ny biriky vita ho voaroaka tsy simba. Tsy fitoeran-javatra fotsiny ny lasitra; Izy io dia fitaovana injeniera mazava tsara izay mamaritra ny fifandraisana misy eo amin'ny fitaovana vaovao sy ny tontolon'ny maritrano sy ny fanorenana.

Ny anjara asan'ny milina simenitra amin'ny fanomanana binder

Amin'ny asa izay mamokatra eco-bricks composite mampiasa binder simenitra, Ny fanomanana ny binder dia dingana lehibe iray izay misy fiantraikany mivantana amin'ny kalitaon'ny vokatra farany. Fomba fanao mahazatra amin'ny fampifangaroana simenitra, rano, ary ny fitambarana hafa dia hiteraka andiany tsy mifanaraka ary, Noho izany, biriky manana tanjaka sy faharetana tsy azo ihodivirana. Eo no tena ilain'ny milina simenitra natokana ho an'ny famokarana feno kokoa..

Ny milina simenitra maoderina dia manamboatra ny fandrefesana marina sy ny fampifangaroana ireo singa binder. Matetika izy io dia ahitana ampahany manan-danja maromaro:

- Silos: Ho an'ny fitahirizana fitaovana betsaka toy ny simenitra Portland, lavenona manidina, ary fasika.

- Weigh Hoppers: Ireo dia apetraka amin'ny selan'ny entana, izay mizana tena marina. The system's controller calls for a specific weight of each ingredient (E.g., 200 kg simenitra, 600 kg fasika), ary ny fitaovana dia arotsaka ao amin'ny hopper mandra-pahatongan'ny lanjan'ny tanjona. Ity fatra gravimetric ity dia marina kokoa noho ny fandrefesana volumetric.

- Meteran'ny rano: Ny metatra mazava tsara dia mifehy ny habetsahan'ny rano ampidirina amin'ny fangaro. Ny tahan'ny rano amin'ny simenitra dia azo inoana fa ny singa manan-danja indrindra amin'ny famaritana ny tanjaky ny simenitra voasitrana.

- Mixer: Indray mandeha nolanjaina, ny singa maina dia latsaka ao anaty mixeur mahery (matetika ny planeta na kambana-shaft mixer), izay atambatra. Ampiana rano avy eo, ary mitohy ny fampifangaroana mandritra ny fotoana voarindra mba hahazoana antoka ny homogeneous tanteraka, slurry tsy misy vongana.

Amin'ny fampiasana milina simenitra, mpamokatra biriky ekolojika dia miantoka fa ny "glue" Ny fihazonana ny fitambaran'ny plastika miaraka dia ny batch tsara kalitao aorian'ny batch. Ity haavon'ny fanaraha-maso ny dingana ity dia fototra. Izany dia ahafahan'ny mpanamboatra miantoka ny fahombiazan'ny vokatra ary manamarina fa mahafeno ny fepetra takian'ny injeniera sy ny kaody fanorenana izy ireo.. Izy io dia mampiakatra ny famokarana biriky fasika plastika avy amin'ny asa tanana ho amin'ny siansa indostrialy, manao ny vina amin'ny fananganana rafitra manontolo avy amin'ny fako ho zava-misy azo antoka sy azo ekena.

Dingana 4: Fitsaboana sy fitsapana – Miantoka ny faharetana sy ny fanarahan-dalàna

Tamin'ny fotoana nandroahana biriky ekolojika vao niforona avy amin'ny milina fanaovana sakana, mbola tsy vokatra vita izany. Izy io dia marefo, "maitso" sakana izay mbola tsy mahatratra ny tanjany sy ny faharetany farany. Ny dingana manaraka, fanasitranana, is a period of chemical and physical transformation that is absolutely essential for the brick's performance. Taorian'ny fitsaboana, tsy maintsy ampiharina ny fitondrana fitsapana henjana. Io no vavahady fanomezan-toky ny kalitao izay miantoka ny fiarovana ny biriky rehetra mivoaka ny orinasa, azo antoka, ary mifanaraka amin'ny tanjona. Ity dingana ity no tetezana eo amin'ny famokarana sy ny fanorenana. Izy io dia manome ny angona azo hamarinina izay manome ny architects, injeniera, ary manorina ny fahatokiana hampiasa ireo fitaovana vaovao ireo. Ho an'izay matotra amin'ny fomba fanamboarana biriky eco avy amin'ny akora fako, Ny fahatakarana ny siansa momba ny fanasitranana sy ny fifehezana ny fitsapana dia tsy azo ifanarahana.

Ny dingana fanasitranana: Metamorphose simika sy ara-batana

Miovaova be ny fizotran'ny fanasitranana arakaraky ny karazana biriky ekolojika vokarina.

- Ho an'ny biriky plastika vita amin'ny Compression: Ny biriky vita amin'ny plastika miempo sy miorim-paka dia mila fomba fitsaboana tsotra, izay voalaza mazava kokoa hoe mangatsiaka. Rehefa mangatsiaka ny biriky mafana, ny rojo polymère voarendrika dia mivaingana ho rafitra semi-kristaly na amorphous. Zava-dehibe ny tahan'ny fampangatsiahana. Raha mangatsiaka loatra, mety hitombo ny adin-tsaina anatiny, mahatonga ny biriky ho mora vaky. Fomba fampangatsiahana voafehy, angamba amin'ny conveyor miadana na ao amin'ny efitrano mifehy ny mari-pana, mamela ireo adin-tsaina hiala sasatra, miteraka henjana kokoa, vokatra stable kokoa.

- Ho an'ny Eco-Brick misy simenitra: Sarotra kokoa sy manakiana kokoa ny fizotran'ny fanasitranana. Tsy ny fanamainana fotsiny no atao; Izany dia dingana simika antsoina hoe hydration. Ny rano mifangaro amin'ny fangaro dia mihetsika amin'ny poti-tsimenitra Portland, mamorona matrix kristaly ny kalsioma-silicate-hydrate (C-S-H) gel. Ity ny "glue" izay mamatotra ny fasika sy ny plastika mitambatra, manome hery ny biriky. Mitaky fotoana sy ny fisian'ny hamandoana izany fihetsika izany.

Mba hanasitranana araka ny tokony ho izy ny biriky simenitra mifatotra amin'ny tontolo iainana, Matetika izy ireo dia afindra any amin'ny faritra fanasitranana voatokana mandritra ny fe-potoana 7 ny 28 andro. Mandritra izao fotoana izao, tsy maintsy hamandoana foana izy ireo. Ny fomba mahazatra dia ahitana:

- Misting/Misting: Afafy rano tsy tapaka ireo sakana.

- firakony: Ny antontam-bato dia rakotra lamba plastika na lambam-pandriana mando mba hamandrihana ny hamandoana sy hisorohana ny etona..

- Steam Curing: Amin'ny asa indostrialy lehibe, Ny blocs dia azo apetraka ao anaty lafaoro manokana izay sitrana amin'ny hafanana, tontolo iainana avo hamandoana. Manafaingana ny fizotran'ny hydration izany, mamela ny biriky hahatratra ny isan-jaton'ny tanjany farany amin'ny kely indrindra 24 ORA, manafaingana ny tsingerin'ny famokarana.

Ny biriky avela ho maina haingana dia ho malemy, feno vovoka, ary porous satria ny fanehoan-kevitra hydration dia hijanona aloha loatra.

Protokol fanomezan-toky ny kalitao: Herin'ny fanerena, Ny fisafotofotoana rano, ary Thermal Resistance

Rehefa sitrana tanteraka, ny biriky dia tsy maintsy andrana mba hanamarina fa mahafeno ny fepetra takiana amin'ny fanatanterahana. Santionany kisendrasendra avy amin'ny andiany famokarana tsirairay dia tokony iharan'ny andiana fitsapana manara-penitra.

- Herin'ny fanerena: Ity no fitsapana manan-danja indrindra ho an'ny fitaovana ara-drafitra na mitondra entana. Ny biriky dia napetraka ao anaty milina fanaovana fitiliana manerantany ary iharan'ny hery fanerena mihamitombo tsikelikely mandra-pahoriana. Ny milina dia mirakitra ny hery ambony indrindra azon'ny biriky. Ny vokatra dia aseho amin'ny megapascals (MPa) na kilao isaky ny santimetatra toradroa (psi). Ohatra, Ny biriky fanorenana tanimanga mahazatra dia mety manana tanjaky ny fanerena manodidina 20 MPa, tanjona iray mety hahatratra na hihoatra ny biriky eco-biriky vita tsara (Mishra et al., 2022).

- Ny fisafotofotoana rano: This test measures the brick's porosity. Biriky maina iray no lanjaina, alentika anaty rano mba 24 ORA, ary nolanjaina indray. Ny fahazoana lanja, aseho ho isan-jaton'ny lanjany tany am-boalohany, dia ny sandan'ny fandraisana rano. Sanda ambany no irina, satria mety hiteraka olana amin'ny fahasimbana amin'ny hatsiaka ny rano be loatra, fitomboan'ny bobongolo, ary ny fitaterana sira amin'ny fanaovana biriky.

- hakitroky: The brick's dimensions and weight are measured to calculate its density. Izany dia famantarana tsara ny tsy miovaova. Ny ampahany amin'ny biriky manana hakitroky be dia be dia manondro olana amin'ny fizotran'ny fampifangaroana na fanerena.

- Conductivity mafana (R-soa): Izany dia mandrefy ny fomba mahatohitra ny fikorianan'ny hafanana ny biriky. Satria ny plastika dia insulator tsara, eco-biriky (indrindra ireo poakaty) matetika dia manana fampisehoana mafana kokoa noho ny bozaka vita amin'ny simenitra. Afaka manampy amin'ny fananganana trano mitsitsy angovo izany.

- Fire Resistance: Tena zava-dehibe amin'ny fiarovana ny trano ny fitsapana ny fihetsik'ilay akora ao anaty afo. Ny fitsapana dia manombantombana ny maha-adiny azy, ny tahan'ny lelafo niparitaka teo amboniny, ary raha mitazona ny fahamendrehany ara-drafitra izy io rehefa tratran'ny hafanana ambony.

Fihaonana amin'ny Lalàm-panorenana sy Fenitra ao amin'ny 2025

In 2025, Ny fampiasana fitaovana fanorenana vaovao dia fehezin'ny rafitra henjana amin'ny fehezan-dalàna sy fenitra momba ny fanorenana, toy ny avy amin'ny ASTM International na ny International Building Code (IBC). Tsy ampy ny mahafantatra tsotra izao ny fomba fanamboarana biriky ekolojika amin'ny akora fako; ny mpanamboatra dia tsy maintsy afaka manaporofo fa manaraka ireo fitsipika ireo ny vokatra.

Mba hahazoana fitaovana vaovao ankatoavina, mazàna ny mpanamboatra dia mila manao fandaharana fitiliana feno, matetika miaraka amin'ny laboratoara nahazo mari-pankasitrahana avy amin'ny antoko fahatelo. Angonina ao anaty taratasin-drakitra ara-teknika sy tatitra momba ny fanombanana ny vokatra. Ity tatitra ity dia mampiseho amin'ny tompon'andraikitra amin'ny fanorenana, mpanao mari-trano, ary ny injeniera fa ny vokatra dia azo antoka ary miasa araka ny voalaza. Mety ho lava sy lafo ny dingana, fa dingana iray tena ilaina ho an'ny orinasa rehetra maniry ny hivarotra ny eco-biriky azy ho fitaovana fanorenana ara-dalàna.. Satria maro kokoa ny orinasa mivezivezy amin'ity dingana ity, novolavolaina ny fenitra manokana ho an'ny fitaovana fanorenana vita amin'ny plastika, manamora ny fidiran'ny zava-baovao eny an-tsena. Ny fanoloran-tena amin'ny fitsapana sy fanamarinana henjana no manasaraka ny tetikasa tombantombana amin'ny asa famokarana matihanina.

Dingana 5: Applications sy Integration – Fanorenana hoavy maharitra

Amin'ny sitrana tanteraka, NIHARAM-PITSAPANA, ary eco-biriky voamarina eny an-tanana, lasa ny fanontaniana farany: inona no azontsika amboarina amin'izany? Ny valin'io fanontaniana io dia miitatra isan-taona satria ny fanavaozana ny siansa momba ny fitaovana sy ny injeniera dia manosika ny fetran'izay azo atao.. Ny fampiharana ho an'ny eco-biriky dia manomboka amin'ny tsotra, singa tsy ara-drafitra izay manatsara ny habaka ho an'ny besinimaro amin'ny fahatsinjovana manaitaitra ny trano iray manontolo vita avy amin'ny fako efa nohavaozina.. Ity dingana farany ity dia ny fampidirana ireo fitaovana vaovao ireo amin'ny fomba amam-panao efa napetraka amin'ny indostrian'ny fanorenana ary mampiseho ny lanjany amin'ny tetikasa tena izy.. Io no faratampony amin'ny dingana rehetra, izay ny foto-kevitra abstract momba ny toekarena boribory dia atao azo tsapain-tanana amin'ny endriky ny rindrina, pavements, sy rafitra izay manompo ny fiarahamonintsika. Ny dia amin'ny fomba fanamboarana biriky eco-biriky avy amin'ny akora fako dia mahita ny dikany farany amin'ny rafitra mahasoa sy maharitra noforoniny..

Fampiharana tsy ara-drafitra: Pavements, Rindrina zaridaina, ary Benches

Ny fampiharana haingana sy miely patrana indrindra amin'ny biriky ekolojika dia amin'ny anjara tsy ara-drafitra na semi-structural.. Amin'ireo fampiasana ireo, ny fepetra fototra dia ny faharetana, fanoherana ny toetr'andro, ary aesthetics, fa tsy hery fanerena avo. Izany no mahatonga azy io ho toerana fidirana tsara indrindra ho an'ny teknolojia eco-brick.

- Paving Blocks: Ny biriky eko-biriky vita amin'ny atiny plastika avo dia mety tsara ho an'ny lalan'ny mpandeha an-tongotra, TOERAM, ary lalan'ny tsingerina. Matetika izy ireo dia maivana kokoa noho ny pavers simenitra mahazatra, izay afaka mampihena ny saran'ny fitaterana sy manamora ny fametrahana. Ny fampiasana milina paver block manokana dia mamela ny famokarana endrika mifamatotra izay mamorona matanjaka, stable surface. Ny fanoherana ny rano amin'ny plastika dia mety ho tombony ihany koa.

- Landscaping sy Garden Elements: Ny foto-kevitry ny biriky tavoahangy dia mety tsara amin'ny famoronana fandriana zaridaina mitsangana, rindrina fihazonana, ary sisin-tany haingon-trano. Amin'ny toe-javatra indostrialy, Ny sakana vita amin'ny milina dia azo ampiasaina amin'ny tetikasa fatra-paniry laza kokoa amin'ny zaridainam-panjakana sy zaridaina manokana. Ny fanoherana azy ireo amin'ny lo sy ny bibikely dia mahatonga azy ireo ho solontena maharitra amin'ny hazo amin'ireo fampiharana ireo.

- Fanaka ivelany: dabilio, latabatra, ary ny mpamboly dia fampiharana tsara ho an'ny biriky ekolojika. Ireo tetik'asa ireo dia fanehoana miharihary ny mety hisian'ny fanimbana ny fako, miasa ho fitaovana fanabeazana eny amin'ny toerana ho an'ny daholobe.

Ireo fampiharana tsy ara-drafitra ireo dia sehatra fanaporofoana tena ilaina. Izy ireo dia mamela ny vahoaka sy ny indostrian'ny fanorenana ho zatra sy mahazo aina amin'ny fitaovana vaovao amin'ny toerana tsy dia mampidi-doza, manangana fahatokisana amin'ny fampiasana azy amin'ny andraikitra sarotra kokoa.

Fandinihana ny mety ho rafitra: Fanavaozana amin'ny Eco-Bricks mitondra entana

Ny grail masin'ny teknolojia eco-brick dia ny fampiasana azy amin'ny rindrina ara-drafitra mitondra entana ho an'ny tranobe.. Ity dia olana ara-teknika sarotra kokoa, satria ny fitaovana dia tsy maintsy mahazaka soa aman-tsara ny lanjan'ny gorodona sy ny tafo nandritra ny am-polony taona maro. Fikarohana sy fampandrosoana manan-danja amin'ny 2025 dia mifantoka amin'io tanjona io.

Ny fahombiazana amin'ity sehatra ity dia miankina amin'ny famokarana biriky vita amin'ny indostrialy, matetika mampiasa binder simenitra. Ny mpikaroka dia manamboatra tsara ny fampifangaroana - ny tahan'ny plastika marina, fasika, simenitra, ary ny additives - mba hampitomboana ny herin'ny fanerena nefa tsy hahatonga ny biriky ho mora vaky. Ohatra, Ny fikarakarana ny endrik'ireo granules plastika mba hahatonga azy ireo hahomby kokoa amin'ny fametahana simenitra dia faritra lehibe amin'ny fikarohana (Ny masoko & Adesina, 2020).

Mivoatra ihany koa ny famolavolana ny biriky. Mampiseho fampanantenana lehibe ny sakana mifamatotra izay mizara entana mitovy kokoa amin'ny rindrina. Ny fomba iray hafa dia ny fampiasana biriky eco ho toy ny famenoana ao anaty simenitra na vy. Amin'ity rafitra ity, ny rafitra dia mitondra ny enta-mavesatry ny rafitra voalohany, raha ny eco-biriky no manome ny rindrina, insulation, ary fisarahana amin'ny afo. Izany dia mamela ny fampiasana biriky ekolojika amin'ny tranobe misy rihana ankehitriny, na dia mbola mitohy aza ny fikarohana momba ny fampiasana azy ireo amin'ny rafitra rindrina mitondra entana feno. Ny fampandrosoana ny hery ambony, Ny biriky ara-boajanahary voamarina dia mety hanova ny trano mora sy ny fanorenana maharitra.

Fandinihana tranga: Tetikasa Eco-Brick nahomby Maneran-tany

Ny mety ho teorika dia zavatra iray; hafa ny fahombiazana eo amin'izao tontolo izao. Manerana izao tontolo izao, Ny tetikasa mpisava lalana dia mampiseho ny fahavitan'ny fanorenana biriky ekolojika.

- Any Afrika Atsimo: Ny orinasa dia mamokatra blocs fasika plastika an-tapitrisa sy bloc core hollow avy amin'ny fako plastika tsy azo ovaina.. Izy ireo dia ampiasaina amin'ny tetikasa trano fonenan'ny governemanta sy ny fampandrosoana ara-barotra, famoronana asa sy fanadiovana ny tontolo iainana miaraka.

- Any Amerika Latina: Sekoly sy foibem-piarahamonina maro no naorina tamin'ny fomba biriky tavoahangy, matetika ao anatin'ny hetsika tarihin'ny fiarahamonina. Raha ara-drafitra tsotra, manana lanja ara-tsosialy goavana ireo tetikasa ireo, manome hery ny vondrom-piarahamonina hamaha ny olan'ny fako sy ny fotodrafitrasa.

- Any Eoropa: Tetik'asa fikarohana mandroso dia manorina trano mpanamory amin'ny fampiasana biriky eco-eco, manara-maso ny zava-bitany maharitra amin'ny toetr'andro mafana. Ireo laboratoara velona ireo dia manome angona sarobidy momba ny fahombiazan'ny angovo, faharetana, ary fampiononana ny mponina, manokatra ny lalana ho amin'ny fananganana malalaka kokoa.

Manakiana ireo fanadihadiana ireo. Izy ireo dia manome ny porofo-ny-hevitra ilaina mba handresena ny fisalasalana. Tsy ny fahafaha-manao ara-teknika ihany no asehon'izy ireo fa ny fiantraika tsara ara-tsosialy sy ara-toekarena amin'ny fampiasana fomba fiasa boribory amin'ny fanorenana.. Izy ireo no porofo azo tsapain-tanana izay mamaly ny fanontaniana ny amin'ny fomba fanamboarana biriky voajanahary avy amin'ny akora fako amin'ny fomba izay sady azo ampiharina no manentana ny fanahy..

Fanamboarana ny lalana amin'ny milina paver block

Raha ny hevitra ny fananganana trano iray manontolo avy amin'ny fako dia misarika ny saina, iray amin'ireo azo ampiharina indrindra, scalable, ary ny fampiharana ara-toekarena ho an'ny biriky ara-tontolo iainana indostrialy dia amin'ny famokarana vato fisaka. Ny tsenan'ny pavers dia midadasika, mandrakotra ny zava-drehetra manomboka amin'ny lalan'ny trano fonenana sy patio mankany amin'ny sisin-dàlana monisipaly sy ny kianjam-bahoaka. Ity fampiharana ity dia mety indrindra ho an'ny fitaovana vita amin'ny plastika, ary ny fampiasana milina paver block manokana dia fanalahidy hamahana izany hery izany.

Ny milina paver block dia variana amin'ny milina fanasan-damba mahazatra, fa optimized amin'ny famokarana ny thinner, matetika mifamatotra, endrika mampiavaka ny vato fisaka. Ny lasitra dia natao mba hamoronana pavers miaraka amin'ny mari-pamantarana avo lenta sy ny sisiny maranitra, izay tena ilaina mba hahazoana tonon-taolana mafy sy ny ambonin`ny vita malama. The machine's combined vibration and pressing action is ideal for the plastic-sand-cement mix, miantoka ny matevina, paver tsy misy porosity izay mahatohitra ny fivezivezena an-tongotra ary manohitra ny tsingerina mangatsiaka.

Ny fametrahana tsipika famokarana mifototra amin'ny milina paver block dia manome tombony maro ho an'ny orinasa biriky eco-biriky vaovao:

- Sakana ara-teknika ambany: Ny fepetra ara-drafitra ho an'ny paving block dia amin'ny ankapobeny dia tsy dia henjana loatra raha oharina amin'ny rindrina mifono mavesatra. Izany dia manome fidirana mamela heloka kokoa amin'ny tsena.

- Tsena avo lenta: Tsy mitsaha-mitombo ny fangatahana pavers, manome fidiram-bola maharitra.

- Aesthetic Flexibility: Ny pigment dia azo ampiana mora foana amin'ny fifangaroana, mamela ny famokarana pavers amin'ny loko isan-karazany sy ny famaranana, mamahana ny fitakiana ara-javakanto sy fanajariana ny tany.

Amin'ny fifantohana amin'ity fizarana ity, afaka manangana ny marika ny orinasa iray, manatsara ny fizotrany famokarana, ary mamokatra ny renivola ilaina mba hivelatra amin'ny vokatra fanorenana mandroso kokoa amin'ny ho avy. Paikady pragmatika izay manome lalana ara-bakiteny sy ara-panoharana mankany amin'ny indostrian'ny fanorenana maharitra kokoa.

Fanontaniana matetika (FAQ)

Karazana plastika inona no tsara indrindra hanaovana biriky ekolojika? Ho an'ny famokarana indostrialy mampiasa milina fanaovana sakana, thermoplastics toy ny High Density Polyethylene (HDPE, #2), Polyethylene ambany (Ldpe, #4), ary polypropylene (p, #5) dia idealy. Mikoropaka tsara izy ireo ary azo levona ho toy ny fatorana na ampiasaina ho toy ny aggregate maivana amin'ny simenitra.. Ho an'ny biriky tavoahangy tsotra, izay madio, MAINA, azo ampiasaina ny plastika tsy azo simbaina.

Azo antoka sy mahatohitra afo ny eco-bricks? Ny fiarovana no tena zava-dehibe. Ny eco-bricks vita amin'ny sehatra indostrialy dia mandalo fitsapana henjana. Rehefa vita amin'ny plastika simenitra matrix, mihena be ny firehetan'ny firehetana. Ho an'ny biriky vita amin'ny plastika, lelafo retardant additives dia matetika tafiditra ao amin'ny famolavolana. Ny biriky eco-biriky ara-barotra rehetra dia tsy maintsy asedraina sy voamarina mba hahafeno ny fenitry ny fiarovana ny afo amin'ny fehezan-dalàna momba ny trano eo an-toerana alohan'ny hampiasana azy amin'ny fanorenana..

Manao ahoana ny herin'ny eco-biriky raha oharina amin'ny biriky mahazatra? Miovaova be ny tanjaky ny fomba famokarana. Ny biriky tavoahangy tsotra dia tsy natao ho an'ny fampiharana mitondra entana. na izany aza, biriky eco-biriky vita amin'ny indostria (plastika-simenitra-fasika) azo amboarina ho matanjaka toy ny, na mahery kokoa noho ny, tanimanga mahazatra na biriky simenitra. Mihoatra ny tanjaky ny compressive 20 MPa azo tratrarina, mahatonga azy ireo ho mety amin'ny rindrina ara-drafitra.

Inona ny milina ilaina hanombohana orinasa famokarana biriky ekolojika? Mety hanomboka amin'ny shredder sy milina hydraulika ny fandidiana kely. Ho an'ny trano indostrialy matotra, ny fitaovana tena ilaina dia ahitana plastika fanasan-damba sy fanamainana tsipika, shredder / granulator indostrialy, mixeur lehibe (toy ny milina simenitra na orinasa batching), ary avo-output milina fanaovana sakana. Fitaovana fanaraha-maso kalitao, toy ny compression tester, dia tena ilaina ihany koa.

Azo ampiasaina hanamboarana trano iray manontolo ny eco-bricks? ENY, fa miankina amin'ny karazana biriky ekolojika sy ny famolavolana trano izany. Amin'ny tetikasa maro ankehitriny, Ny biriky eco dia ampiasaina ho famenoana ao anaty simenitra na vy, izay mitondra ny enta-mavesatra ara-drafitra lehibe. Rindrina feno enta-mavesatra vita amin'ny fanamarinana, Manjary zava-misy ihany koa ny biriky ekolojika matanjaka, indrindra ho an'ny trano misy rihana. Tena ilaina ny miara-miasa amin'ny injeniera ary manaraka ny fitsipiky ny fanorenana eo an-toerana.

Inona no fiantraikan'ny tontolo iainana amin'ny famokarana biriky ekolojika? Ny fiantraikan'ny tontolo iainana amin'ny ankapobeny dia tena tsara raha ampitahaina amin'ireo safidy hafa. Ny dingana dia mamily ny fako plastika amin'ny fanariam-pako na ranomasimbe, ary mampihena ny fangatahana fitaovana virjiny toy ny tanimanga izany, shale, sy simenitra. Raha ny fizotran'ny famokarana mihitsy no mandany angovo, Ny fanombanana amin'ny tsingerin'ny fiainana amin'ny ankapobeny dia mampiseho fa ny tombotsoa azo avy amin'ny fampihenana ny fako sy ny fanoloana ny fitaovana nentim-paharazana manenika karbônina dia manan-danja..

Ahoana ny fomba fiasan'ny eco-biriky amin'ny resaka insulation? Ny eco-bricks matetika dia manome insulation mafana tsara kokoa raha oharina amin'ny biriky mafy na tanimanga. Ny plastika dia insulator voajanahary, koa mampihena ny famindrana hafanana ny fampidirana azy ho biriky. Tena mandaitra ny biriky eco-biriky hollow, satria ny rivotra voafandrika ao anatin'ny banga dia manome sosona insulation fanampiny, izay mety hitarika ho amin'ny trano mitsitsy angovo kokoa izay mitaky hafanana sy mangatsiaka kokoa.

Lafo kokoa noho ny biriky mahazatra ve ny biriky eco? Mety hifaninana ny vidiny. Na dia mety ho ambony aza ny fampiasam-bola amin'ny milina, ny akora (plastika fako) matetika maimaim-poana na loharanon-karena mihitsy aza (raha karamaina ianao haka azy). Ny vidiny farany dia miankina amin'ny vidin'ny asa, vidin'ny angovo, ary ny haavon'ny fandidiana. Any amin'ny faritra maro, mipoitra ny biriky ekôlôjia ho safidy lafo vidy amin'ny fitaovana fanorenana nentim-paharazana, indrindra ho an'ny tetikasa trano mora.

Famaranana

Ny dian'ny fanovana ny fako ho fitaovana fanorenana sarobidy dia fitantarana mahery vaika amin'izao androntsika izao. Izy io dia miresaka momba ny fahaiza-mamorona sy ny fampifanarahana manoloana ireo fanamby mahatahotra ny tontolo iainana. Ny dingana amin'ny fananganana biriky ekolojika amin'ny akora fako, rehefa nasandratra avy amin'ny asa tanana tsotra ho amin'ny siansa indostrialy, manolotra lalana azo tsapain-tanana mankany amin'ny toekarena boribory. Fitsipi-pifehezana mitaky synthesis ny simia izany, INJENIORIA, ary logistics, tarihin'ny etika momba ny faharetana avokoa. Ny fampiasana milina be pitsiny — manomboka amin'ny tsipika fanasokajiana mandeha ho azy ka hatramin'ny milina fanakanana mandeha ho azy tanteraka — dia tsy momba ny fahombiazana fotsiny.; momba ny tsy fitoviana izany, fiarovana, ary ny fahafahana mamokatra vokatra azo antoka izay afaka mahazo ny fitokisan'ny indostrian'ny fanorenana.

Ny eco-brick dia mihoatra noho ny fomba tsara hanafenana plastika. Fanehoan-kevitra izany fa ireo fitaovana noheverinay ho tsy misy vidiny taloha dia manana sanda voajanahary miandry ny hidy.. Amin'ny alàlan'ny rafitra rafitra, MIOMANA, mamorona, ary manao fitiliana ireo fitaovana ireo, isika dia afaka mamorona singa izay tsy vitan'ny hoe mahasoa ny tontolo iainana fa tsara ara-drafitra sy ara-toekarena ihany koa. Eo am-piandrasana ny fananganana tanàna sy vondrom-piarahamonina maharitra amin'ny ho avy, ny biriky ekôlôjia manetry tena dia mijoro ho porofon'ny hevitra fa ny fototra ho an'ny tontolo maharitra kokoa dia mety ho hita ao amin'ireo zavatra efa nariantsika..

References

Ny masoko, t. O., & Adesina, ny. (2020). Fako plastika ho an'ny vokatra fanorenana: sata, fetra sy fomba fijery ho avy. Fandinihana tranga momba ny fitaovana fanorenana, 12, e00330.

Azevedo, ny. R. G., Cecchin, D., Tashima, M. M., Viana, H. F. N., & Marvila, M. T. (2022). Famerenana momba ny fanamafisana ny fako plastika amin'ny indostrian'ny fanorenana. Journal of Materials Research and Technology, 21, 449-462.

Mishra, G., Sahoo, S., & pandà, S. (2022). Famerenana feno momba ny fampiasana sy ny fahombiazan'ny eco-bricks. Materials Today: fitsarana, 62(P6), 3326-3331.

Public Health England (PHE). (2017). Ny fampiasana ny plastika recycle amin'ny fanorenana sy ny fampiharana hafa. PHE Publications.